Custom Silicone Rubber Compression Molds for Bellows

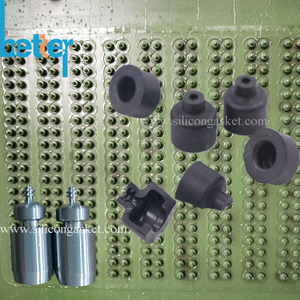

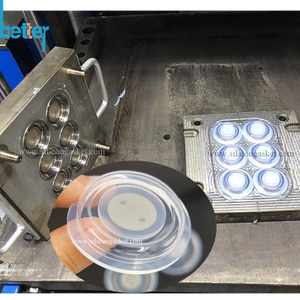

Rubber Compression Molds, also called as Silicone Compression Molds and Rubber Compression Moulds, is used for Rubber Compression Molding, Curing rubber material and make it into a piece of work with the particular shape and size for your application, such as Silicone Rubber Gaskets & Seals, Rubber Bellows, Rubber Grommet, etc.

Rubber Compression Molds are essentially important for product quality, production efficiency and function, usually affected by the several factors: mold Steel, mold design structure, Mold Manufacturability analysis, etc. Here, we will talk about influence on product caused by mold design structures.

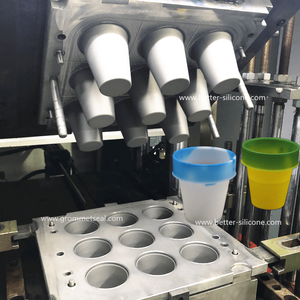

Rubber Compression Molds have different design structure based on Manufacturability & Moldability analysis, customer’s requirements and the function of workpiece, usually including Two-Plate Mold and Three-Plate Mold.

Two-plate Mold is the most typical, commonly-used mold, the simplest mold, and the most reliable mold for simple-structure of product. And it has simple mold design structure, thus low cost, less lead time and shorter cycle time & higher production efficiency compared with Three-plate mold.

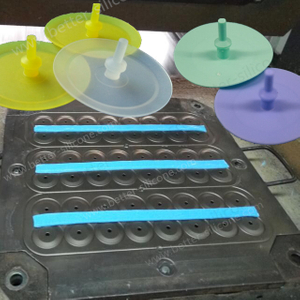

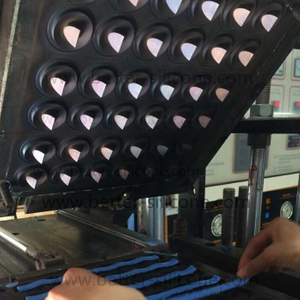

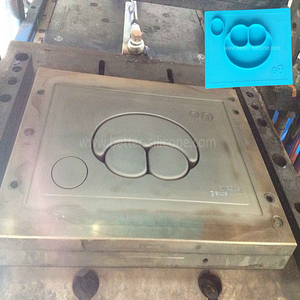

Three-Plate Mold is more complex than two plate mold, which has an additional mold plate between upper plate and down plate. Based on product design structure, customer’s demands and moldability analysis and working of product. Some three-plate molds have movable middle plate manually and others have fixed middle plate on Press Machine. For some much more complex products, three-plate molds have middle plates, and also have many moving core & inserts & sliders.

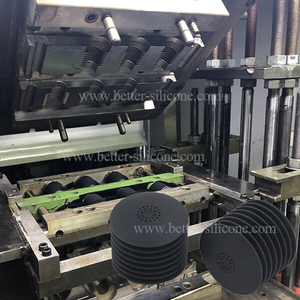

1. Three-plate molds have movable middle plate manually

2. Three-Plate Molds have fixed middle plate on Press Machine

3. Three-plate molds have middle plates, and also have many moving core & inserts & sliders.