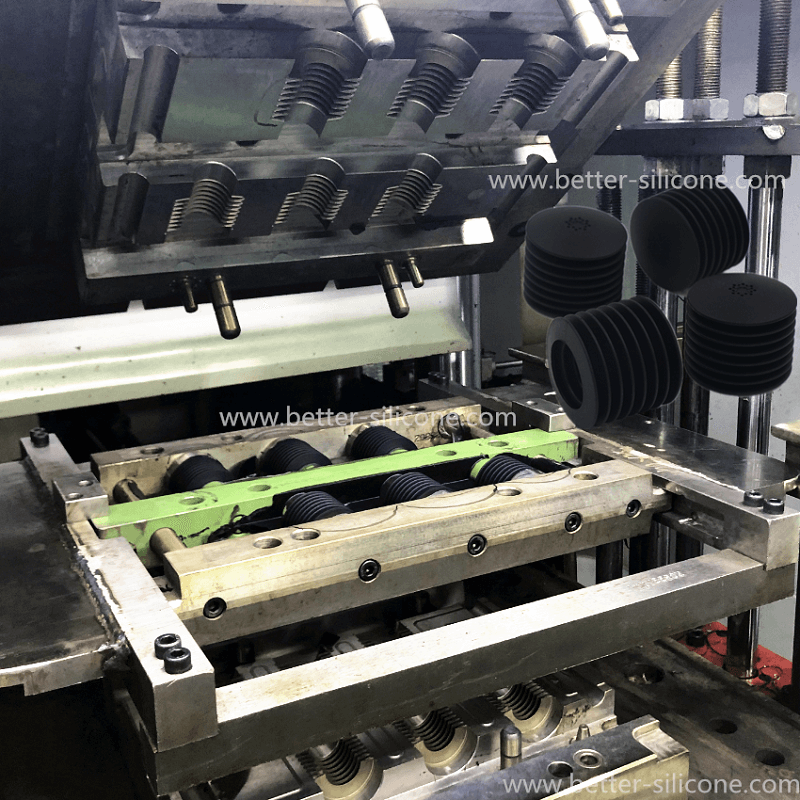

Rubber Grommet Compression Molding

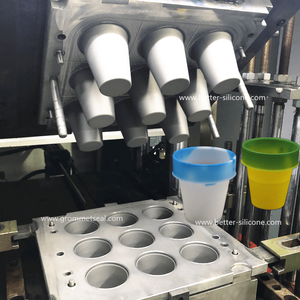

Rubber Compression Molding, also known as Silicone Compression Molding, Rubber Compression Tool, Compression Moulding Process. Rubber Compression Molding process starts with making uncured rubber performed to proper shape and size. Then placing the rubber perform onto the bottom mold cavity or cavities. Closing the mold, rubber material is compressed under pressure and temperature to fill in the mold cavities to be shaped to rubber parts. At last mold is open after a certain time. Removing compressed rubber parts from the mold and next circle begins.

Rubber Compression Molding Structure

Rubber Compression Molding is a traditional and relatively simple process tin rubber industry. It mainly suitable for producing large rubber parts and simple structure rubber parts. Such as rubber seal rings, rubber washers, and other rubber gaskets etc. Their compression mold is most simple, which is composed by two parts: top plate and bottom plate

But with the advances in manufacturing technology, including adopting high quality steel to make molds, using accurate location pins, with mature rubber compression molding technology and experience. We are also able to produce complicated, tight tolerance and high precision rubber parts by rubber compression moulding now.

Such as high precision rubber seal gasket, rubber bellows and rubber grommets etc. The compression mold structure is more complicated. It’s a tree plate compression mold. Except top plate and bottom plate we also need a core, a keel or a middle plate according to the product structure.

Take the rubber grommet for example. As the rubber grommet is with undercuts, using a middle plate is a good choice to produce good appearance rubber grommet without large parting line.

For the rubber parts with complicated structure, we also can adopt rubber compression mold with blocks. The blocks can hold all sides of the part, making better location. It is very crucial in making good appearance products with small flash.

When the rubber grommet is with deep undercuts and the material is hard, it is difficult to demold them from middle plate. In this situation, we should adopt the compression mold with a keel to solve this problem.

As a top custom rubber compression molding manufacturer, we are able to make rubber compression molds in most suitable structure according to your product configuration. Our mature rubber compression molding process allows us to manufacture high precision, tight tolerance, and virtually flash free custom molded rubber components. We invite you to visit our website to learn more about our services or email us today.