Silicone Rubber Compression Mold Rubber Material Guide for Seals.pdf

Rubber Material Guide for Seals.pdf

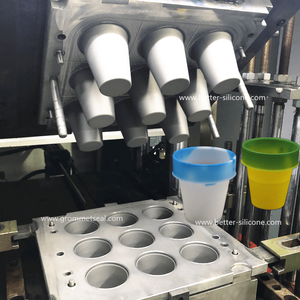

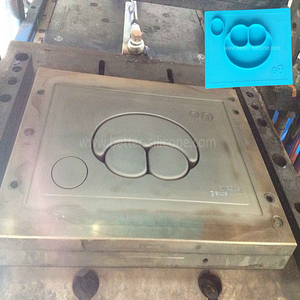

Rubber Compression Mold is also named as silicone compression molding, and rubber compression tool. Compression mold is simple molding that widely used to produce thermoplastic and silicone rubber products, like nitrile seals, EPDM grommet, silicone o rings, or neoprene gaskets. The basic structure of compression mold is with two plates, upper plate and mold plate. Product shapes are carved in the mold plate, which call mold cavities or chambers.

Rubber Compression Molding Process

Rubber Compression Mold is pre-heated before vulcanization. Specific raw material are put into the cavities. Then mold tool close and compression machine apply pressure to the mold. With pressure and heat, raw material can flow evenly to each chamber. After seveal minutes in specific temperature, rubber part shapes are formed. The temperature and pressure is crucial to rubber seals curing. Temperature is not enough high, rubber seal gasket may not fully cured. But if temperature is too high, rubber seals may crack. Silicone rubber compression molding temperature is about 160-180°C.

Curing time of rubber seals should depend on rubber gasket geometries, seal weight and the thickness.

Rubber Compression Mold Types

Rubber Compression Mold is one the most cost-effective tool to make rubber seals or other silicone rubber parts. From the mold structure perspective, compression Molding includes four types, two basic plates mold, basic plates with middle plate, two basic plates with mold core, and basic mold plates with sliders.

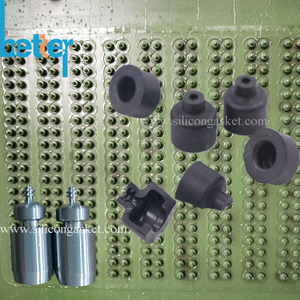

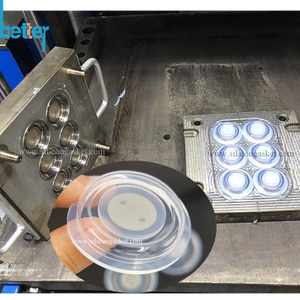

Two Basic Plates Compression Mold

It is the most common and simple rubber compression mold. There are only two tool plates. Product cavities are in these two plates. This kind of compression molding press is suitable for simple rubber part, like silicone o ring, flat nitrile rubber gasket.

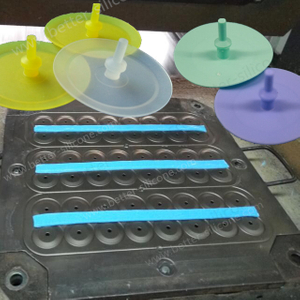

Rubber Compression Mold with Two Plates and Middle Plate

This compression mould is suitable for rubber products with small undercut, like rubber grommet seal. Grommet with small undercut and sofer durometer (about 30 shore A - 60 Shore A), can be made by silicone rubber compression molding with middle plate.

When demould the silicone grommet seal, we need to take out the middle plate, and stab the cured rubber grommet seal out from the middle plate.

Regarding the parting line, it is invisible in the undercut of rubber grommet.

However, if a grommet seal with large undercut and high hardness (like 80 Shore A), it is not appropriate to make the grommet by middle plate compression molding, because it is very difficult to demould rubber grommet seals from the plate. For this kind of rubber product, it can be made by rubber compression mold with mold cores.

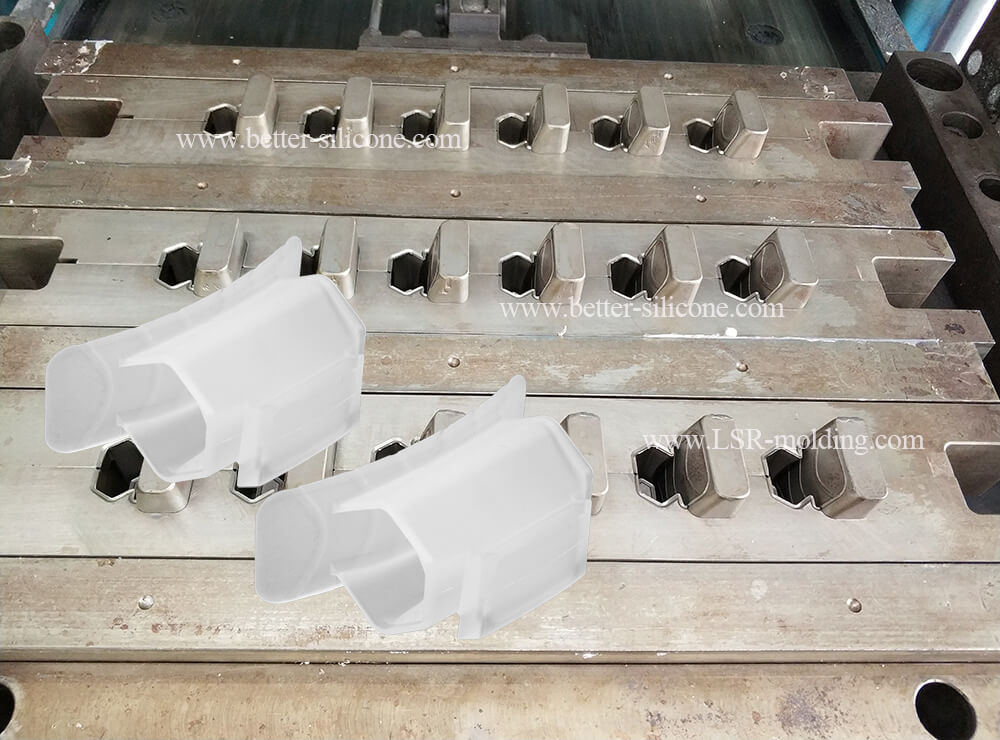

Silicone Rubber Compression Mold with Mould Cores

Compression Mold with mold cores is suitable for product with deep undercut and cylinder shape rubber parts, like grommet, and silicone bottle sleeve. Rubber parts are demoulded from the mold cores. Parting line are on both sides of the rubber part.

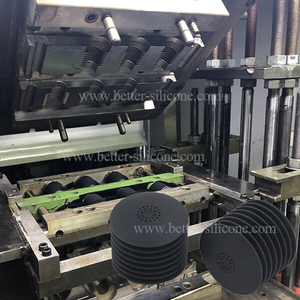

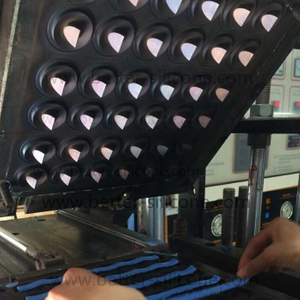

Silicone Rubber Compression Mold with Sliders

Regarding the complex rubber parts with deep under or hollow cylinder shapes, compression mold design can be Sliders Compression Molding.

However, with sliders, production cycle time is longer because sliders need to be taken out to demould the rubber seals. Besides, compression mould mechanical life is shorter than other mould types. Parting lines in silicone rubber seals will become obvious as rubber compression mould shot times increase.

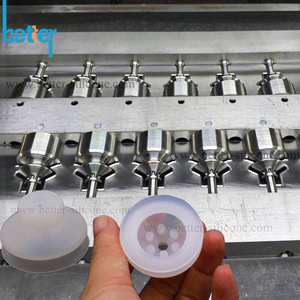

Precision Rubber Seals Compression Mold

Better Silicone has engaged in compression molding rubber seals production for more than 6 years. We specilaized in producing high-precision nitrile seals, neoprene gasket, silicone o ring gasket, EPDM rubber washer etc. For rubber compression mould, we can control the flash less than 0.07mm, some can with minimum 0.03mm flash. For liquid silicone injection molding, silicone rubber gasket can be without any flash.

Besides the minimum flash, rubber parts consistency in wall thickness, product quality and properties are guaranteed in Better Silicone.