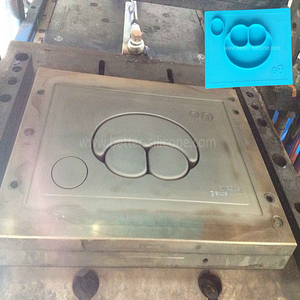

Rubber Compression Molding

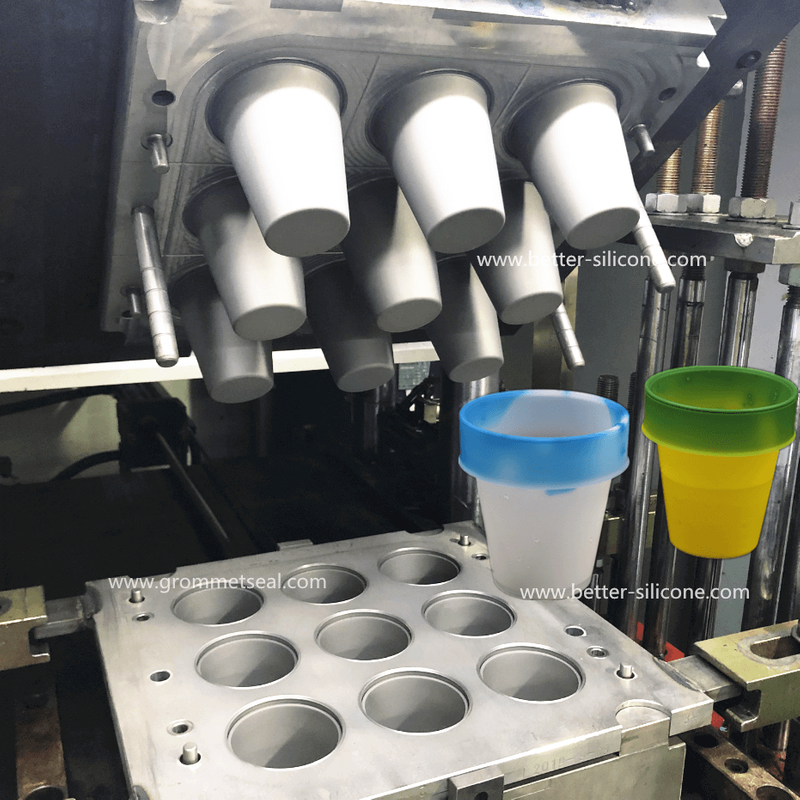

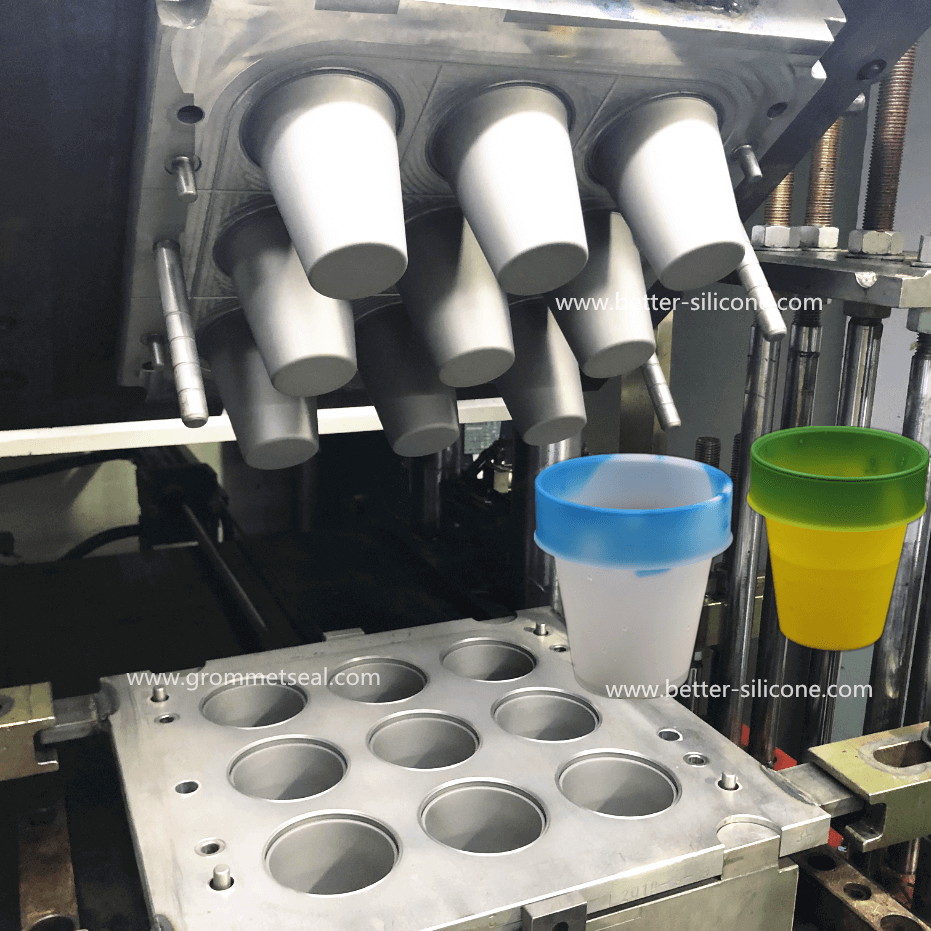

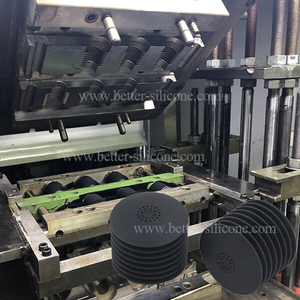

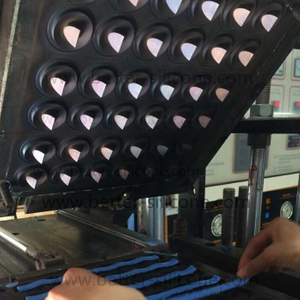

Rubber Compression Molding includes Silicone Compression Molding, EPDM Rubber Compression Molding, Nitrile Rubber Compression Molding and Neoprene Rubber Compression Molding etc. Compression molding is to place an uncured rubber compound which has been formed to the proper shape and size based on the finished part configuration into an opened rubber mold cavity, then the mold is closed. Rubber material is compressed under the high pressure and high temperature to fill in the mold cavities to be shaped to a rubber part or parts. The mold remains closed until the rubber is cured. After a predetermined amount of time the mold is opened and the finished parts are de-molded from mold cavities.

Rubber Compression Molding Progress:

1. Making uncured rubber performed to proper shape and size.

2. Placeing rubber preform into mold cavity.

3. Closing the mold. Rubber material be shape to a product under pressure and temperature.

4. Removing compressed rubber parts from the mold and deflashing.

Rubber Compression Molding Advantages:

• Mold tool is cost-effective.

• Short tooling time.

• Widely-used for different size parts.

• Higher percentage material utilization than transfer molding.

• Suitable for most elastomer and cure systems.

Rubber Compression Molding Disadvantages:

• Unsuitable for complex moulding

• Not easy to control flash.

• Longer process time.

• Labor intensive, add labor cost.

Rubber Compression Molding Structure

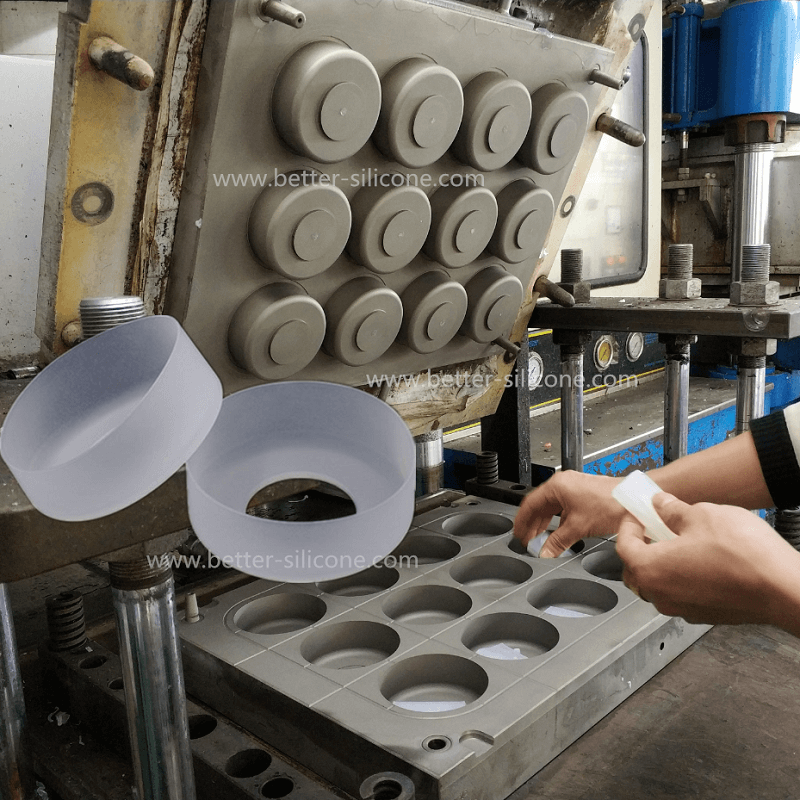

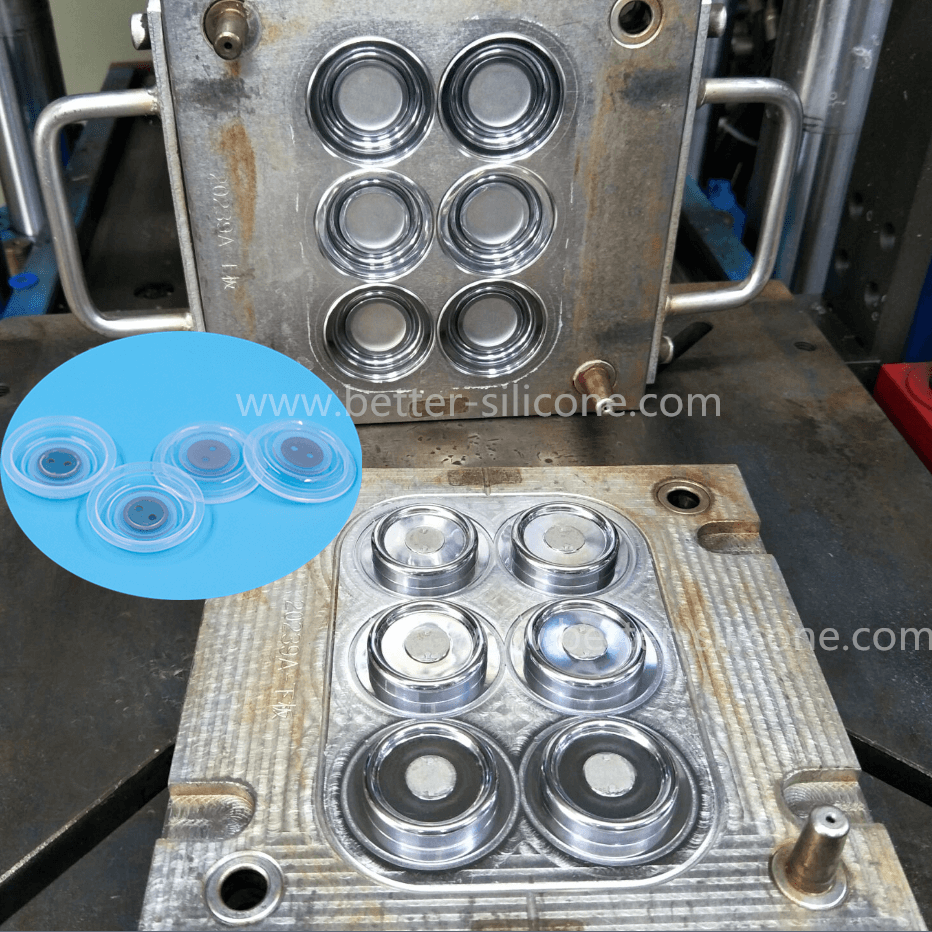

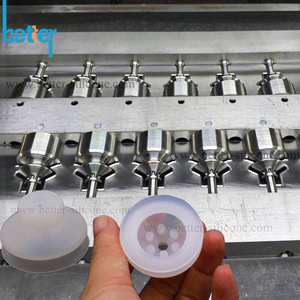

• For simple structure rubber parts compression mold, such as rubber seal rings, rubber washers, there are only a top plate and a bottom plate. It's the most simple compression mold.

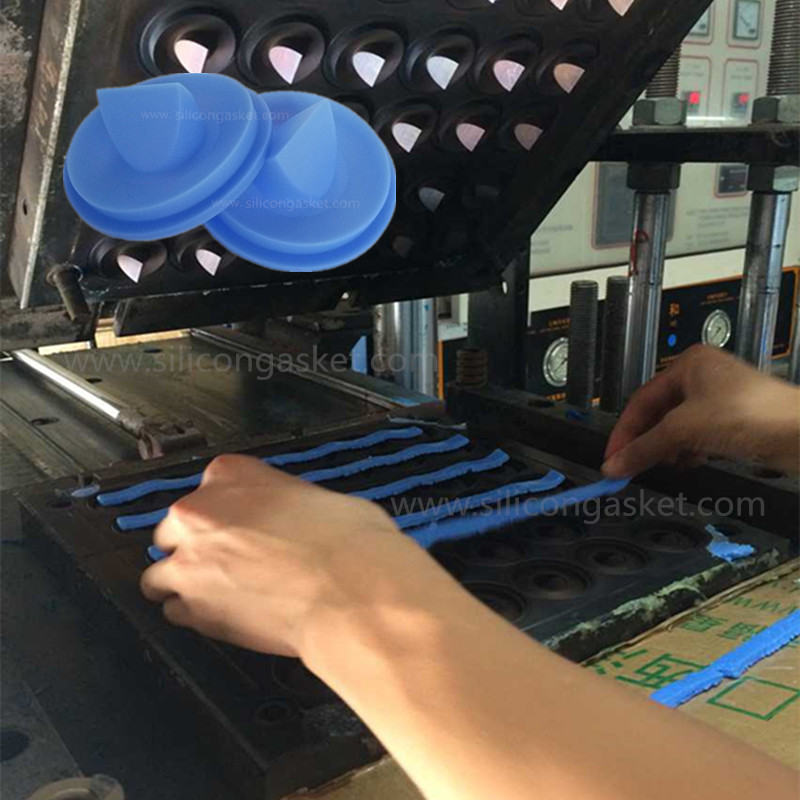

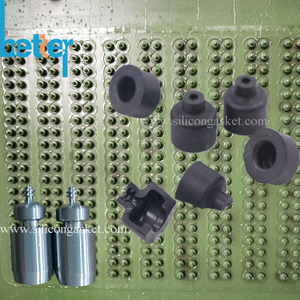

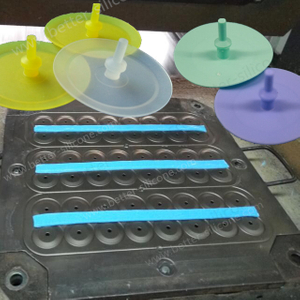

• For rubber parts with undercuts, such as rubber grommets compression mold, rubber valves compression mold, there are a top plate, a medium plate and a bottom plate.

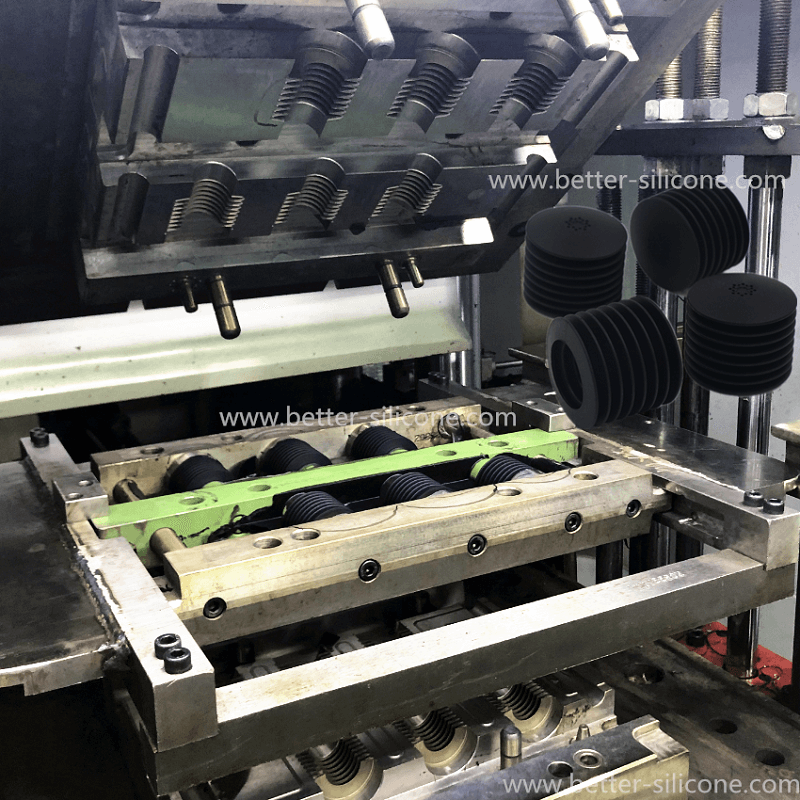

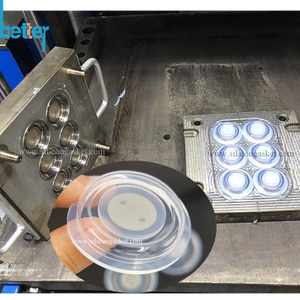

• For rubber parts with a hole(the inner part is empty), such as rubber bellows compression mold, rubber bushings compression mold, there are a top plate, a moving core and a bottom plate.

Rubber Compression Molding for Rubber Seal Ring with Two Plate

Rubber Compression Molding for Rubber Grommet with Three Plate

Rubber Compression Molding for Rubber Bellow with Moving Core