Liquid Silicone Injection Molding for Liquid silicone parts/products

Liquid Silicone Injection Molding, also called Liquid Silicone Molding, LSR Molding & Liquid Injection Mold (LIM) , Silicone Injection Mould, Liquid Silicone Rubber Injection Moulding, which can produce liquid silicone rubber gasket & seal, accessorries or products by horizontal and vertical Liquid silicon injection moudling machines. LSR silicon rubber injection mold is safer, more precise & environmentally friendly & transparent, using less manpower, and having high production efficiency compared with rubber compression mold.

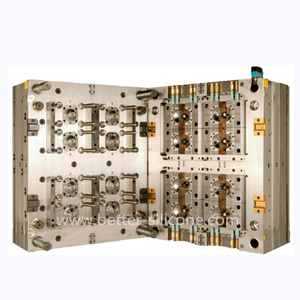

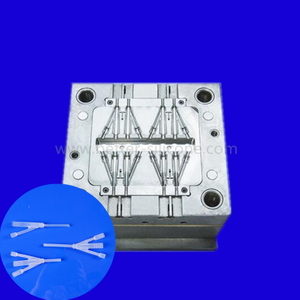

Liquid Silicone Injection Mold has two different kinds of runner systems: Hot Runner System and Cold Runner System. For Cold runner system, there are two types as well: cold runner with shut-off valve and cold runner without needle valves.

Hot Runner Silicone Injection Mould

Hot runner silicone injection mould without needle valve, only need distributive mixing andn liquid silicone rubber feeding systems. This kind silicone injection mold suits for low-volume LSR injection molded production, do not have tight tolerance requirement LSR products, like LSR baby nipple bottle, silicone breast pump, and many babycare products that only need to make sure safety and appearance. For these products, hot runner system silicone injection mould is ok, can meet customers requirement and also save mold cost.

Liquid Silicone Rubber Mold Tooling is Safer:

Liquid Silicone Rubber molding can produce medical grade silicone gasket & seal, face mask, even implant boby silicone products or medical device etc.

Liquid Silicone Rubber Molding also can produce food grade silicone baby products like silicone baby nipple, silicone baby bottles, silicon pacifiers etc.

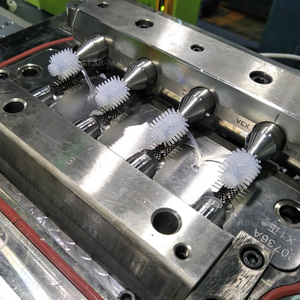

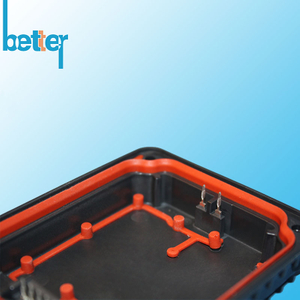

Liquid Silicone Mould More Precise: not only in design and size/dimension tolerance, silicone rubber flashing, parting line, but also in plastic or metal + liquid silicone rubber over molding products.

Liquid Injection Moulding More Environmentally friendly and less manpower:

Silicone compression mold, workers need work in high temperature for keeping mold temperature during production. Silicone rubber compression accessories need a lot of labor for removing burrs / flash.

Silicone Injection production, like plastic injection, operates in 100,000 grade clean room and suitable temperature conditions. Some of them is auto flashing cutting.

High production efficiency: liquid silicone rubber molding, such as plastic injection, production time is short compared with compression molding.