Silicone Compression Molding for Rubber Gasket

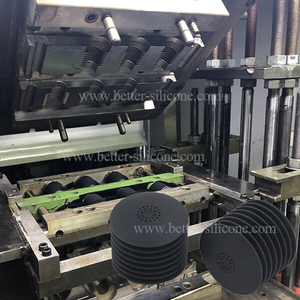

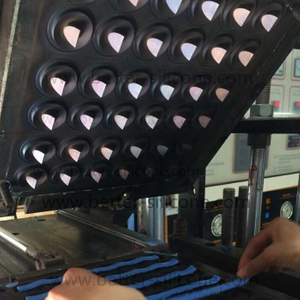

Silicone Compression Molding for Rubber Gaskets process begins with a piece of uncured silicone rubber which has been performed to a controlled weight and shape. This preform is placed directly into the silicone rubber mold cavity prior to mold closure. As the mold is closed, the material is compressed between the plates causing the compound to flow to fills the cavity. The material is held in the mold under high pressure and elevated temperature to activate the cure system in the silicone rubber compound (silicone rubber is vulcanized). The cycle time is established to reach an optimal level of cure. At the end of the cycle, the parts are removed or ejected from the cavities and the next cycle begins. Products produced by Xiamen Better Silicone proprietary compression molding process can be designed to be high precision, low waste, and near flash-less out of the mold.

Advantages of Silicone Compression Molding for Rubber Gasket

Silicone Compression Mold Tooling of Rubber Gaskets can be less complex and lower cost compared to LSR Injection Molding.

Rubber Compression Molding will be lower percentage material waste vs. traditional LSR injection molding or transfer molding

More Options of Compression Moulding Materials: Compression molding is suitable for flexible materials, as parts can remain pliable after the curing process. Additionally, thermosets are available to mold multiple cavities, which opens up many options when it comes time to select a molding material. Commonly used materials include silicone gaskets, natural rubber gaskets, and EPDM gaskets, NBR Gaskets..

Short set-up times, allowing materials and colors to be changed quickly

Faster mold manufacturing turnaround time

Disadvantages of Silicone Compression Molding for Rubber Gasket

Due to the limitation of mold structure & compression molding way, it is hard to achieve the non-flash effect, but we can minimum the flash, for rubber parts, we can minimum the flash at 0.075-0.02mm. (industry standard is for rubber parts is ±0.2mm)

Higher Human Capital Investments: As previously mentioned, flash is removed manually on compression molds, which generates higher labor costs. It is hard to achieve automation unless the product structure is quite simple & production volume is large.

Slower Cycle Time: The time needed to start and repeat the sequence of operations is between 1-6 minutes for compression molds; a much slower cycle time than injection molding.

Lower Productivity: When flash (the resin that escapes between two parts) occurs, it must be manually trimmed, thus slowing down productivity. Additionally, you’re unable to regrind this excess material, which creates more waste.

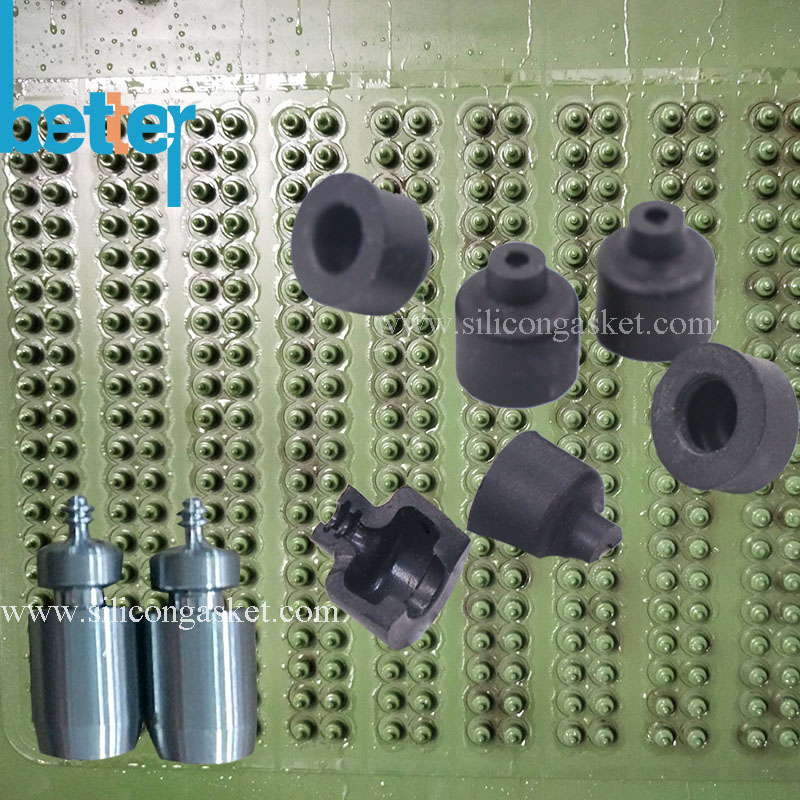

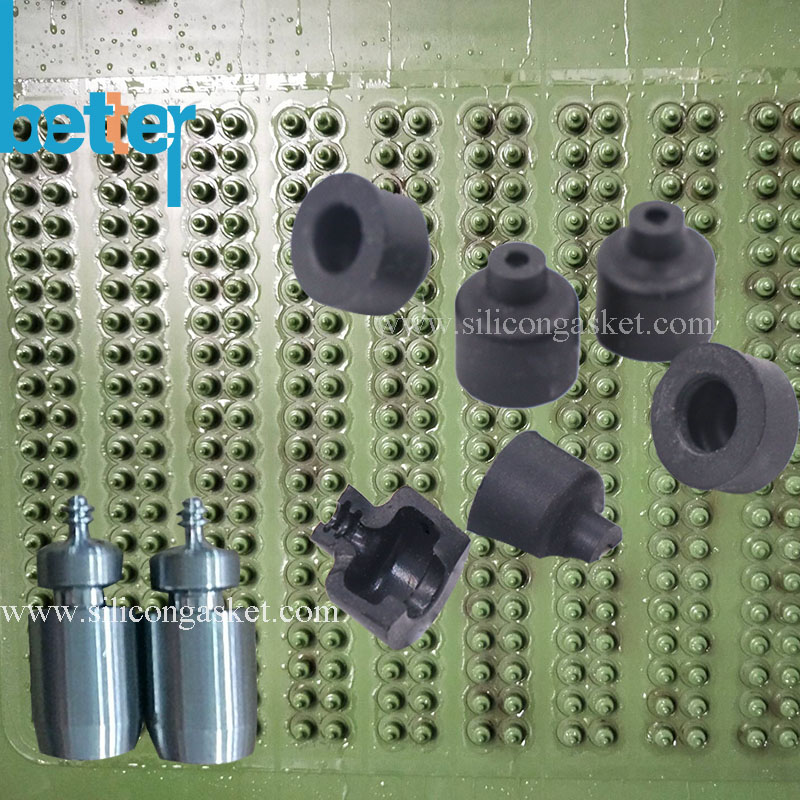

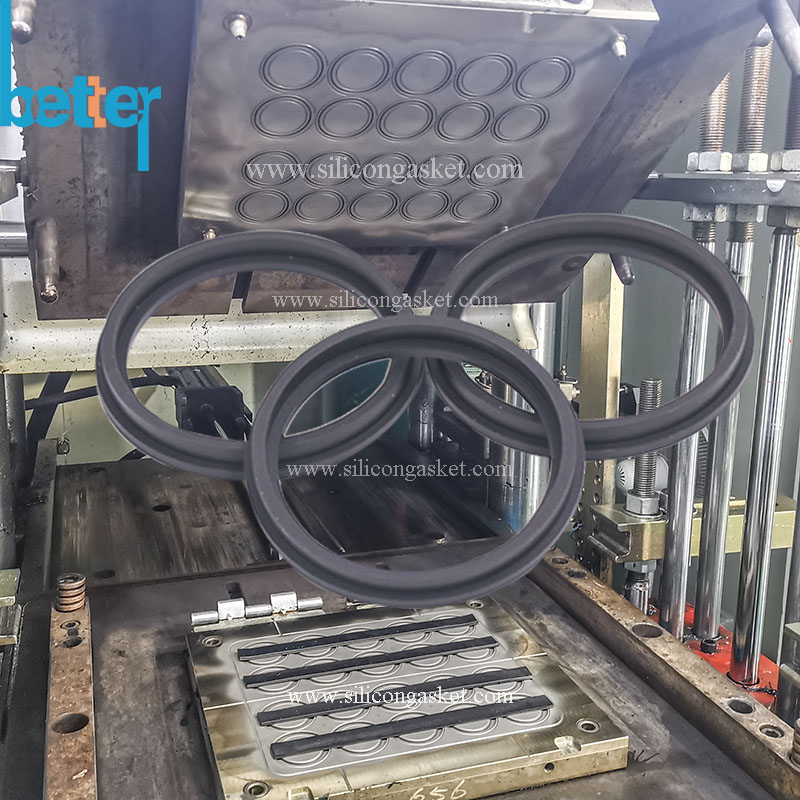

Silicone Rubber Compression Molding Types

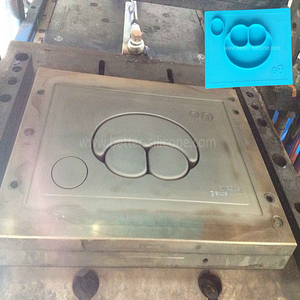

Two Plate: for Simple part designs typically only require a two plate mold, which includes a cavity side and a core side.

Three Plate: For part designs with hole or undercuts, it will require to add a middle plate, like silicone grommet, rubber grommet, etc.

Silicone Compression Molding of Rubber Gasket with 2 plate

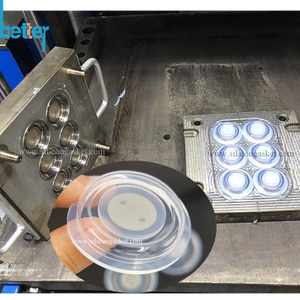

Silicone Compression Molding of Rubber Grommet with 3 plate

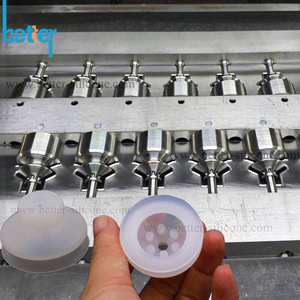

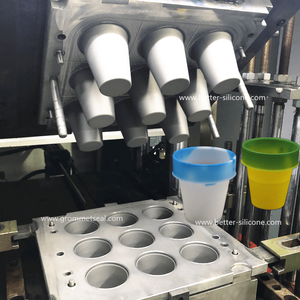

Silicone Compression Molding of Silicone Sleeve with Moving Core

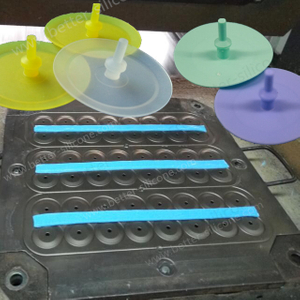

Silicone Compression Molding of Forehead Pad with Sliders

Silicone Rubber Compression Molding Materials

Silicone Rubber Compression molding is suitable for many types of flexible materials, like NBR, CR, EPDM, Silicone, etc.

NBR Gasket chemical stability is good, processing performance is good, with its structure of acrylonitrile content in the relative density increases, the curing speed, tensile strength increased, but resilience would decline, cold resistance variation.

Notes: FDA NBR/ Nitrile Rubber is sturdy enough to handle suction and discharge for food and dairy products. It withstands temperatures of -40°F to 212°F. FDA NBR known for its high resistance to animal fat and vegetable oils. FDA Nitrile (Buna-N, NBR) is typically black or white in color.

Natural Rubber Gaskets (NR Gaskets) have high elasticity & highabrasion, excellent tear resistance & electric insulation, good wear-resistance & drought tolerance, good integrated performance than other materials, while it doesn’t work well in oxygen and ozone resistance, also doesn’t work well in oil and solvent resistance & heat resistance.

Chloroprene/ Neoprene Rubber Gaskets (CR Gaskets) have good Physical Properties, Oil resistance, heat & flame resistance, sunlight resistance, ozone resistance, acid and alkali resistance and chemical resistance. The cold tolerance and storage stability are not very well. Tensile strength, elongation, reversible crystalline and adhesion are good. Aging resistance, heat & oil resistance and chemical resistance are excellent.

EPDM Gaskets have excellent anti-oxidation, anti-ozone and anti-erosion properties. good resistance to weather, ozone, water, chemicals, which can be used for alcoholic & carbonylic components, sealing under high temperature steam environment, bathroom equipment, auto radiator & braking systems. However, EPDM is not recommended for food application or exposure to mineral oil.

Silicone Rubber Gasket Application

Scientific Research & Pharmaceutical Equipment

Door And Windows Seal

Food Processing Equipment Gasket

Glass/Shower Door Seal

Oven Gasket

Optial Fiber Cable Gasket

Military Device & Equipment Seals

Rubber Connector for Electrical Parts

Gaskets for Fuel Tanks, Boilers and Other Closed Vessel

Water Filteration And Purification Equipment

Dairy fluid handling tubing

Peristaltic tubing

Automotive electrical enclosure seal

Electrical Silicone connector

High voltage insulation

Plunger Seal