Rubber Compression Molding for Silicone Bellows

To Download Different Rubber Properties Guides  Rubber Material Guide for Bellows.pdf

Rubber Material Guide for Bellows.pdf

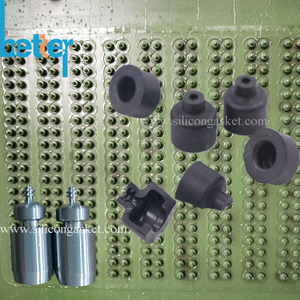

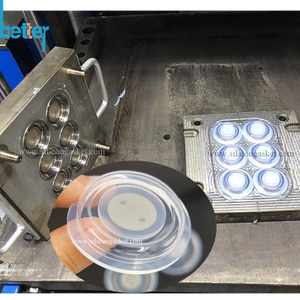

Rubber Compression Molding is also known as silicone compression mold, or compression tool which is used to produce rubber or some thermoplastic part, like silicone valves, nitrile seals, epdm bellows or neoprene grommet.

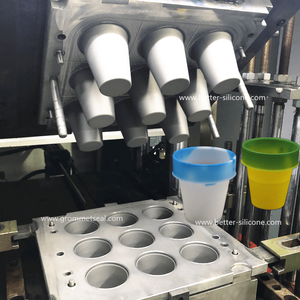

Rubber Compression Molding is semi-automatic. Before curing, rubber mold need to be preheated. Specific pre-measured unvulcanized silicone rubber is place to the mold tool cavities (chamber). Then mold close, and heat and pressure is applied, in order to make raw material flow evenly to each chamber. After several minutes, silicone rubber bellows are cured into solid geometry part.

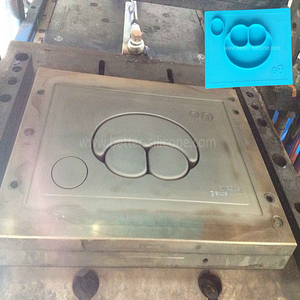

Rubber Compression Molding is a traditional, simplified rubber mold tool, which is suitable for cost effective large volume rubber part production. In general, there are two mould plates, upper plates and lower plate. Sometimes it is a three mould plate structure, a middle plate (or mold core) is between the upper mold plate and lower mould plate, like a sandwich, to produce some complex rubber part, like rubber grommet.

Rubber Compression Molding for Silicone Bellows Advantages

Rubber Compression Molding is one of the most cost effective production way.

Because of its simple molding structure, rubber compression mold development cost is cheaper. With the developemnt of technology, compression molding is coverted to transefer compression molding which is also a kind of ecomical molding.

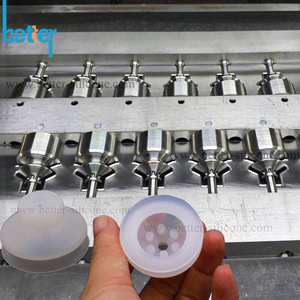

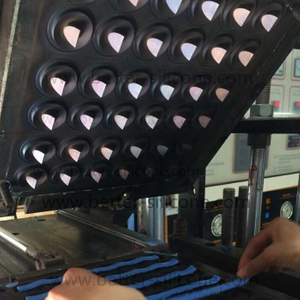

Moreover, more mold cavities are compatible to rubber compression molding plate. Therefore, production effeciency can increase by increase the cavities. It is also suitable for large volume production.

Rubber Compression Mold is also suitable for complex geometry rubber part production, and high-precision silicone rubber parts production.

People may think compression molding only appropriate for simple rubber product. But with accuracy location pins, better mold steel like P20, mature compression molding technology and experience, compression molding can also produce complicated, and high precision rubber products.

Rubber Compression Molding Defects

Rubber compression molding production is not completely automatic.

Before bellow curing, raw material rubber need to be weighted and put into cavities manually. After curing, we also need to take out the silicone bellows manually. Thus, labor force cost to extent is higher than injection molding.

Only for some simple and standard rubber parts, like silicone rubber o-ring seals, it is easy to demould them from mold cavities. Manipulate bellows can be used to demould to increase production efficiency. However, it is hard to demould the rubber bellows from mold cores. We need use air blow gun to take out bellows by hand.

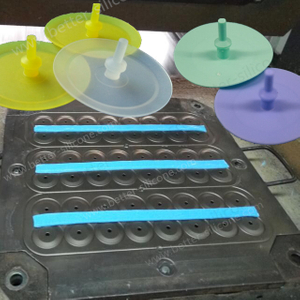

By rubber compression molding, there are flash in rubber bellows or other rubber parts' parting lines.

It is inevitable that flash occurs in rubber bellow parting lines (joint lines) by compression molding, because compression molding structure is simple, and location pines can not be extremly accurate.

Silicone Rubber Compression Molding Production will cause more waste raw material.

Due to the flash, more raw material need to add to compression tool cavities. After compression, the flash will be removed and trimmed.

Our Rubber Bellows Quality

With mature rubber compression technology, we can assure silicone rubber bellows consistency. The wall thickness is even. We can see that the parting line of bellow is very small.

The flash of compression molded rubber seal can be controled within 0.03-0.075mm.