Compression Moulding Process for Rubber Bellow

Rubber Compression Moulding is the oldest way to produce rubber products. Normally, Rubber Compression Moulding process consists of compressing uncured rubber between heated mold plates in a hydraulic press. The uncured rubber has been formed to the proper shape and size based on the finished part configuration. The heat and pressure compress the rubber material to the shape of the cavity and vulcanization occurs after a predetermined time. The product is removed from the mold and the cycle repeated. Preparing rubber material, placing rubber on the bottom plate and removing compressed rubber parts are all by hand.

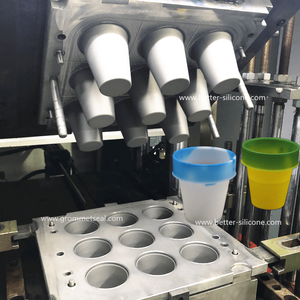

Types of Rubber Compression Mold

1. Two plates rubber compression mold. It’s the most common and simplest compression mold structure. It consists of top plate and middle plate. It mainly suitable for producing large rubber parts and simple structure rubber parts. Such as rubber seal rings, rubber plates, rubber washers, and other rubber gaskets etc.

2. Rubber compression mold with two plates and middle plate. This mold is suitable for producing rubber parts with undercuts. It makes products with good appearance rubber grommet without large parting line. Such as rubber grommet, rubber valves.

3. Rubber compression mold with two plates and mold core or keel. This kind of mold is mainly used for producing rubber parts with a hole or deep undercuts. Such as rubber bellows, rubber sleeves and rubber grommets.

4. Rubber compression mold with two plates and slider blocks. When the material is hard and the undercuts is deep, middle plate and mold core is no longer suitable for producing it. Two plates and a mold core are the best rubber compression mold structure to produce good appearance. And it is easier to demold.

Material of Rubber Bellows for Rubber Compression Molding

EPDM Rubber Vellow with good properties of weather resistance, anti-zone, electric insulation, abrasion resistance and tear resistance. Working temperature: -45C ~ 150C

Silicone Bellow & VMQ Bellow Joint with good properties of weather resistance, acid and alkali resistance, food grade and wide working temperature range: -40C ~ 230C.

Fluoro-Silicone Rubber & FVMQ Expansion Bellow is noted its good mechanical properties and resistance to organic solvents and tetroleum basic fluid.

Neoprene(Chloroprene) Rubber Expansion Bellows with good properties of weather resistance (behind EPDM Rubber) and oil resistance (ranking only after Nitrie Rubber) .

Viton & Fluoro-Rubber Bellows and Boots not only have good weather resistance, oil resistance, but also have high weather resistance, up to 200 C

Common Defects of Rubber Compression Molding for Rubber Bellows

1. Big flashing - This defect is mainly caused by mold design. So an appropriate mold structure is very crucial. And the production technology is also very important. Enough molding pressure makes the flash to be removed easier.

2. Mold misalignment & uneven wall - This defect is mainly caused by inaccurate mold location. Using good quality steel to make molds and use accurate mold location can avoid this problem. But the mold is more complicated and costly, and the production process is slower as the operator removes the mold cores more slowly than simple mold structure.

3. Lip cracking - The reasons for this defect include unsuitable material hardness & durometer, product tool and die-cutting tool.

Advantages of our rubber bellows by compression moulding

1. Suitable compression mold design and good quality steel and accurate location for tools,

2. Mature rubber compression molding technology and rich production experience,

3. Adopt right material in suitable material hardness & durometer.

4. Strict quality control for all rubber bellows

All mentioned above make us to produce good quality bellows with small parting line, small flash and even wall. We are able to minimize the tolerance at 0.02-0.1mm. (Industrial standard for compression molded parts is ±0.2mm)