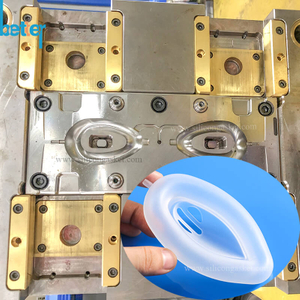

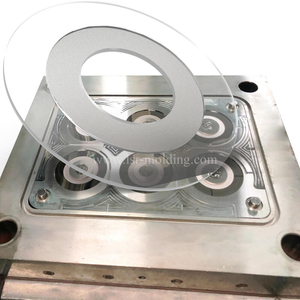

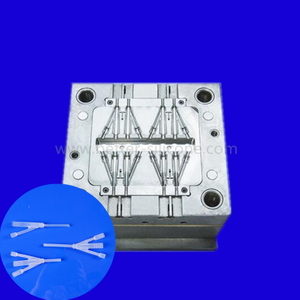

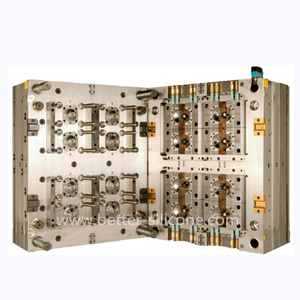

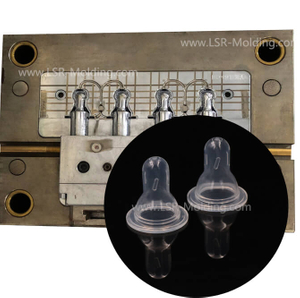

Precision LSR Injection Mold for Liquid silicone parts/products.

LSR Injection Mold, Liquid Silicone Injection Molding, and Liquid Silicon Molding, is also called LSR Molding & LIM, which can produce liquid silicone rubber gasket & seal, accessorries or products by Liquid silicon injection moudling machines. Not by traditional silicone rubber compression machines using traditional production method, but by LSR silicon rubber injection mold production, which is safer, more precise & environmentally friendly & transparent, using less manpower, and having high production efficiency compared with rubber compression mold.

LSR Injection Molding More Precise: not only in design and size/dimension tolerance, silicone rubber flashing, parting line, but also in plastic or metal + liquid silicone rubber over molding products.

LSR Injection Mold Tooling More Safe:

Liquid Silicone Rubber molding can produce medical grade silicone gasket & seal, face mask, even implant boby silicone products or medical device etc

Liquid Silicone Rubber Molding also can produce food grade silicone baby products like silicone baby nipple, silicone baby bottles, silicon pacifiers etc.

LSR Injection Moulding More Environmentally friendly and less manpower:

Silicone compression mold, workers need work in high temperature for keeping mold temperature during production. Silicone rubber compression accessories need a lot of labor for removing burrs / flash.

Liquid silicone injection production, like plastic injection, operates in 100,000 grade clean room and suitable temperature conditions. Some of them is auto flashing cutting.

High production efficiency: liquid silicone rubber molding, such as plastic injection, production time is short compared with compression molding.

Our Advantage:

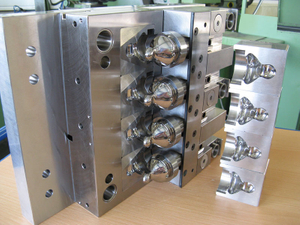

1. Precision Mold-Making Technology (Since 1998)

2. Competitive Price: Origin Manufacturer.

3. Five experienced designers (two of them joined better since 2000 years):

offer technology/production/design/artwork support etc.

4. Production and Test strictly according to ISO9001.

5. Complete Production Plant, Equipment, Environment

1. Five Plants:

Mold-Making, Silicone Rubber Compressive, Plastic Injection, LSR Injection,

and Assembly Plants.

2. Mold-Making Equipment:

CNC, Mirror EDM, EDM, Slowspeed Wire Cut M/C and other auxiliary equipment etc.

3. Production Equipment:

15 Sets Rubber Compressive Machines, 8 Sets Haitian Plastic Injection Machines, 2 Sets LSR Injection Machines.

4. Test Equipment:

3D Projectors, Sealing Testor, Elasticity Measurement, Durometer etc.

5. Dust-free Environment:

LSR injection Machines, 3 Sets Rubber Compressive Machines, and Assembly Line in 100,000 rating Dust-free Plants.

6. Fast-reaction Organization:

Such as, One morning, Our Customer tell two precision rubber parts for smart cell phone need to revived, and ask we to send revived rubber samples to them at that day. At last, we made it at that day.