Electrically Conductive Elastomer Electrically Conductive Elastomer is a generic term referring to any rubberized material with conductive properties, such as glass silvering, silver-plat aluminum, silver, etc. These kind of conductive particle are well - dispersed in the silicone rubber. Conductive network forms when the neighboring conductive particles contact under pressure. It reduces or eliminates the EMI/RFI (electromagnetic interference and radio frequency interference) noise that is often associated with electronics.

Conductive Rubber includes following several major types:

CONSIL-NC (graphite nickel plating filled in silicone rubber)

CONSIL-V (silver filling silicone rubber extrusion padding)

CONSIL-A silicone rubber (aluminum silver)

CONSIL-N (nickel plated silver filled in silicone rubber)

CONSIL-C silicone rubber (copper plating silver)

SC-CONSIL (graphite filled in silicone rubber)

CONSIL-R silicone rubber (fine silver)

CONSIL-II (silver filled in silicone rubber molded gasket)

Electrically Conductive Elastomer Feature

Electrically Conductive Elastomer main function is to seal and electromagnetic shield.

Notes:

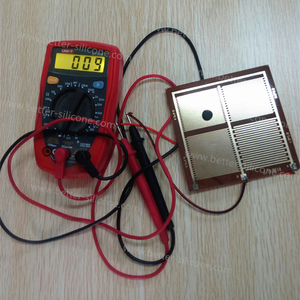

Electrically Conductive Elastomer has electromagnetic shielding function, when the volume resistance is less than 10 ohm.cm. Mainly applied in electromagnetic shielding occasion, also used in the chassis, cabinets, shelter electronic and microwave waveguide system, connector pad, etc.

Electrically Conductive Elastomer:the lower the resistance, the higher the hardness. When the resistance is below 10ohm.cm, the hardness is over 70 shore A.

Electrically Conductive Elastomer Applications

Electrically Conductive elastomer often refers to rubber material, whose volume resistance is within 10^9 ohm.cm. Conductive rubber can provide a good electrical conductivity (Inhibition of frequency 40 GHZ) with its good electromagnetic sealing and water vapor sealing ability. Its volume resistivity can be 0.004 ohm. cm, with good stability.

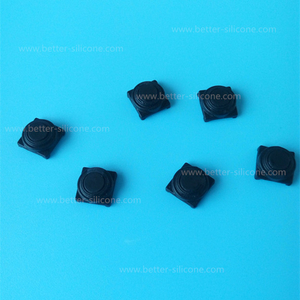

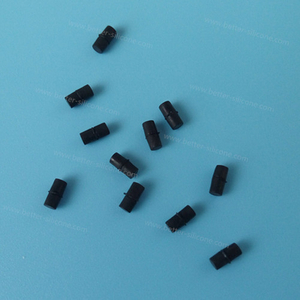

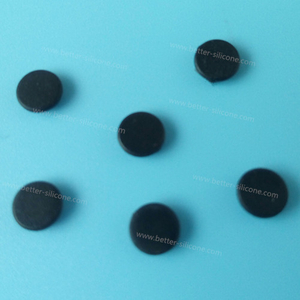

Electrically Conductive elastomer is used in both military and commerce. Main function is to seal and electromagnetic shield. Products can adopt compression molding or extrusion molding. It is on chip or other cutting shape. Shielding performance is as high as 120 dB (10 GHz). Electrically Conductive elastomer is also used in medical electrode. Volume resistance of conductive rubber is bigger compared with that of metal, based on volume resistance is proportional to the distance, the longer the distance, the greater the resistance. Electrically Conductive elastomer has been widely used on the medical electrode. Electrode is thinner, generally below 1 mm, conductive rubber is completely electrified in this case.

Electrically Conductive Elastomer Main Principles

Conductive particles filled inside the electrically conductive elastomer reach a certain volume number, and contact one another, finally form electron continuous state. When strong electromagnetic wave in external electromagnetic field hits free electrons in conductive particles, forming an opposite electromagnetic field, internal and external electromagnetic field offset each other to weaken the effect of electromagnetic interference wave.

Electrically conductive elastomer another principle is energy transformation, in other word, law of conservation of energy. When electromagnetic wave hits free electrons, conductive particles generate heat in the process of electrons movement, which is electromagnetic interference wave - free electron movement kinetic energy-thermal energy, in order to weaken the electromagnetic interference.

Electrically Conductive Elastomer Structure

Electrically Conductive elastomer must be subject to certain compression force to good electrical conductivity, Therefore, the structure must be designed to ensure proper pressure. Optimal amount of compression plates is in height from 7 to 15% ; solid round , D -shaped highly compressed optimum amount of 12 to 30% ; tubular , P-shaped highly compressed form optimum amount of 20 to 60%.

Electrically Conductive Elastomer Material Choice

When working with electrically conductive elastomer , it’s important to remember that galvanic compatibility will also have an effect on which wire type or filler should be used. in this case, a conductive wire type or filler choice needs to be made where the difference in voltage potential between the dissimilar metals are as small as possible.

A widely popular form of conductive rubber is electrically conductive elastomer. Conductive elastomer can be die-cut to form a flat gasket but one of the large differences from other materials is that electrically conductive elastomer can also be provided in a variety of different extruded profiles. These profiles can be extruded as a solid cross section or hollow depending on the compression required and height of the open aperture to be shielded. In electrically conductive elastomer the base rubber is usually comprised of compounds such as silicone, fluorosilicone, or EPDM (ethylene propylene diene monomer). For example, silicone is used for general weather sealing and high temperatures to 400 deg. Fluorosilicone is used for applications where exposure to jet fuel, gasoline, and alcohols are present. EPDM is used for applications where exposure to coolants, steam, phosphate ester.

After choosing a specific rubber suited for the intended environment, a conductive filler must be determined. Some of the most common conductive metal fillers used are silver aluminum, silver glass, silver copper, and nickel graphite.Determining the right filler is dependent on the level of shielding needed for a specific application, the more conductive the filler the higher the level of shielding achieved.