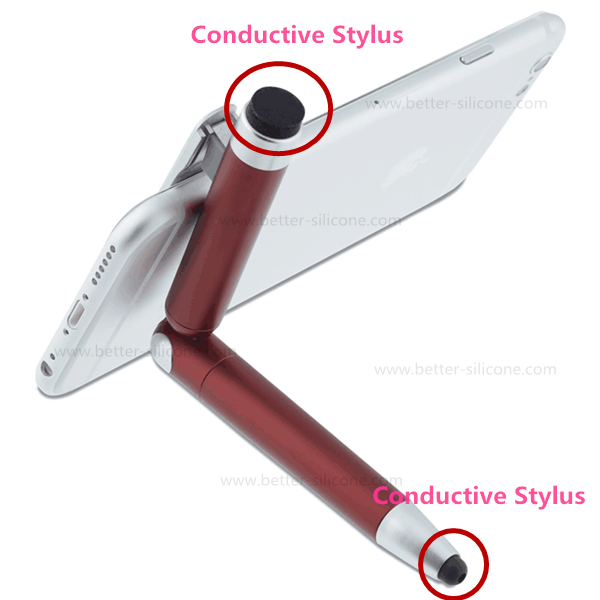

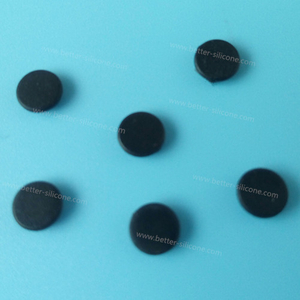

Conductive Rubber Touch Stylus

Conductive Rubber Touch Stylus provides a unique and convenient way for touch screen smart phone owners to control and interact with their device. We offers a kind of high-quality stylus pens that work with a number of different touch screen phones.

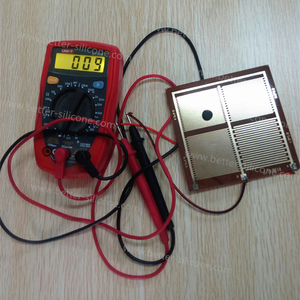

Conductive Rubber Touch Stylus is one of conductive rubber applications which were specially designed to be used with a stylus pen. Conductive rubber is a generic term referring to any rubberized material with conductive properties, such as glass silvering, silver-plat aluminum, silver, etc. These kind of conductive particle are well-dispersed in the silicone rubber. Conductive network forms when the neighboring conductive particles contact under pressure. It reduces or eliminates the EMI / RFI (electromagnetic interference and radio frequency interference) noise that is often associated with electronics.

Conductive Rubber includes following several major types:

Conductive Rubber includes following several major types:

CONSIL-NC (graphite nickel plating filled in silicone rubber)

CONSIL-V (silver filling silicone rubber extrusion padding)

CONSIL-A silicone rubber (aluminum silver)

CONSIL-N (nickel plated silver filled in silicone rubber)

CONSIL-C silicone rubber (copper plating silver)

SC-CONSIL (graphite filled in silicone rubber)

CONSIL-R silicone rubber (fine silver)

CONSIL-II (silver filled in silicone rubber molded gasket)

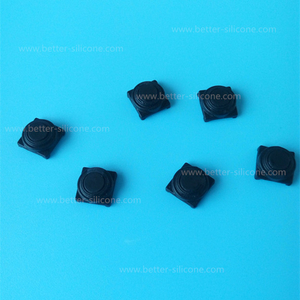

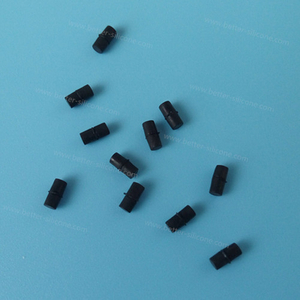

Conductive Rubber Touch Stylus Specifications

Conductive Rubber Touch Stylus made with conductive rubber with high polymer abrasion -resistant coating

Conductive Rubber Touch Stylus never scratch the screen

Conductive Rubber Touch Stylus is compatible with Capacitive Touch Screen

Conductive Rubber Touch Stylus is compatible with for iPhone/iPad/ iPod touch

Conductive Rubber Touch Stylus gives you smooth touch and incredible Abrasion Resistance

Conductive rubber tip stylus----a widely popular form of conductive rubber.

OEM/ODM Service:

1. Main design and Sizes: Offer 2D/3D design drawings, other basic information. Or tell us

your ideas.

2. Materials: Silicone, NBR, NR,EPDM,SBR or TPU, LSR etc.

3. Hardness (Shore A) Demands

4. Telorance Demands, Surface Demands, and so on

5. Package Demands.

Quick Quotation Requirements

| 1. | Drawings Demands: | Offfer 2D/3D drawings or other basic information |

| 2. | Materials Demands: | Silicone, NBR, EPDM, SBR etc or TPU, LSR |

| 3. | Hardness (Shore A) Demands |

| 4. | Telorance Demands, Surface Demands, Anti-fire demands etc. |

| 5. | Package Demands: |

Our Advantages:

1. Precision Own Mold-Making Technology (Since 1998)

2. Competitive Price: Origin Manufacturer.

1.) Mold-Making Plant

2.) Silicone Rubber Compression Plant

3.) Plastic Injection Plant

4.) Liquid Silicone Rubber Injecton Plant (LSR)

5.) Assembly Plant.

3. Five Experienced Designers and Engineers

4. Production and Test strictly according to ISO9001.

Test Equipment: 3D Projectors, Sealing Testor, Elasticity Measurement, Durometer etc

5. Production Environment

6. Rapid Reaction Organization: Support Customer at short time