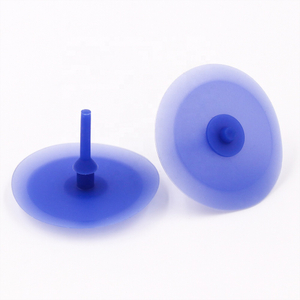

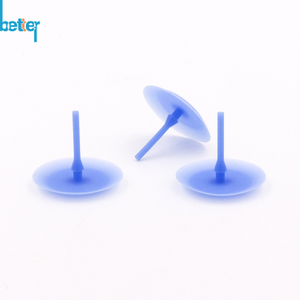

Silicone Duckbill

Duckbill valves are unique, one-piece, elastomeric components that act as backflow prevention devices

or one-way valves or check valves. They have elastomeric lips in the shape of a duckbill which prevent

backflow and allow forward flow.

The main advantage of duckbill valves over other types of one-way valves is that duckbill valves are self

contained i.e. the critical sealing function is an integral part of the one piece elastomeric component as

opposed to valves where a sealing element has to engage with a smooth seat surface to form a seal.

Therefore duckbill valves are easily incorporated and assembled into a wide variety of devices without the

hassle or problems associated with the surface finish quality of mating seats and/or complex assembly

processes.

Other not less important features include:

1)Position independent,

2)Low opening pressure- immediate free flow,

3)Non-tortuous flow path,

4)High flow rate vs. package size,

5)Virtually no internal volume and dead space,

6)Particle compliant,

7)Corrosion resistant,

8)Wear resistant and

9)very cost effective.

One way valves are used for controlling the direction of flow of a fluid. Designs can include umbrella valves, duckbill valves, Belleville Valves and diaphragm valves etc.

One way valves can be designed to provide the customer's required head loss and flow rate for particular applications.

A range of materials and designs are available to handle different fluids and service conditions.

Silicone Duckbill Valve, mostly used in the Patient Valve for Manual Resuscitator.

| Silicone Duckbill Valve |

| Materials | Silicone, LSR(liquid silicone rubber) |

| Materials Demands | Medical/Food Standards |

| Materails Certification | FDA, LFGB, ROHS, SGS etc. |

| Working Temperature | -40oC - 230oC |

| Durometer/Hardness | 30-90 Shore A |

| Opening Ways | Die Cuting (punching) or Crash Cutting |

| Color | Available |

| Prodction Environment | Clean Room |

| Packing Requirement | Air in packaging bag to prevent deformation |

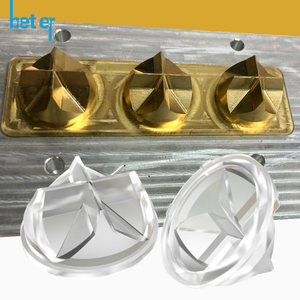

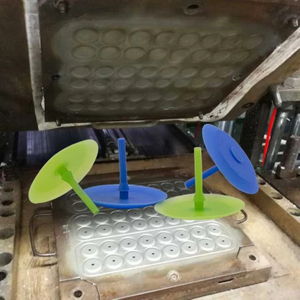

Our Advantage: 1. Own Precision Mold Tooling Making Technology (Since 1998 year) 2. Competitive Price: Origin Manufacturer.

Our Advantage: 1. Own Precision Mold Tooling Making Technology (Since 1998 year) 2. Competitive Price: Origin Manufacturer.

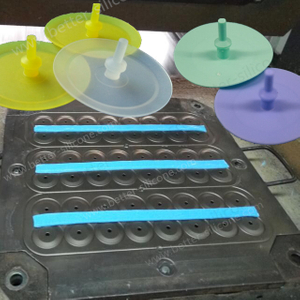

1.)Four Production Plant: Mold Tooling Making Plant; Silicone Rubber Compression Plant; Plastic Injection Plant; Liquid Silicone Rubber Injection Plant(in 100,000 grade Clean room);

2.) One 100,000 Grade Clean Room Assembly Plant. 3. Five e xperienced technical persons:

Offer technology/production/design/artwork support etc. 4. Production and Test strictly according to ISO9001:2008. Test Equipment: 3D Projectors, Sealing Testor, Elasticity Measurement, Durometer etc. 5. Dustfree Environment:

LSR injection Machines, Assembly Line in 100,000 rating Dust-free Plants. 6. Fast-reaction: Xiamen Better Silicone Co.,Ltd is your partner in the development, manufacturing and worldwide distribution of miniature, self-actuating valves and elastomeric valve components for innovative products. Particularly one-way valves and pressure relief valves such as duckbill valves and umbrella valves, dispensing valves and access valves. We supply to Original Equipment Manufacturers (OEMs) in the healthcare, automotive, appliance, water handling and food and packaging industries. Products Development Our technical department develops miniature fluid control components for both our catalog as well as for your specific custom requirements:

1.Precision Own Mold-Making Technology since 1998. 2. In-depth knowledge of silicone rubber compression production. 3. Mature Experience of avoid out of shape and damage from Production to Shipment: Materials Choice, Design Improvement and Packing Information. 4. In-depth knowledge of fluid control technology. 5. In-depth knowledge of elastomer as an engineering material 6. Rapid prototyping with full sizes production equipment and production materials. (Liquid Silicone Injection Machines, Silicone Rubber Compressive Machines) 7. Experienced clean room and precision manufacturing technology. These seven competencies allow us to take a quick and integrated approach when designing a new part, taking function, quality and cost simultaneously into consideration. Manufacturing Our main manufacturing processes are: Precision Mold-Making, Silicone Rubber Compressive Production, Liquid Silicone Rubber (LSR) Injection Production, Plastic Injection Production and Assembly. Most processes (except mold-making) are running in a clean room environment