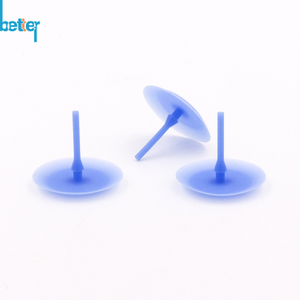

Duckbill Valve

Duckbill valve is also known as a Duckbill check valve, a Rubber Check Valve, a flexible back pressure valve, a duck bill valve, and a slow closing rubber check valve.

Duck bill valve material can use food grade silicone or rubber. If there is no internal pressure,

the duckbill outlet will close on its own as the internal pressure gradually increases the duckbill outlet and the

liquid is drained at high flow rates.

The valve opens when the corresponding pressure medium gas flows through the valve. As the flow rate or pressure increases the degree of opening of the duck bill valve, it also increases When the flow of water stops, the backwater pressure or atmospheric pressure will firmly push the duckbill valve to prevent backflow of liquid or gas. The pressure required to open the duckbill valve is very low. The pressure of the small duck bill valve produced is generally 1 to 5 kPa. With the duckbill valve opening and closing conveniently and sealing well, duckbill valve backflow can be effectively prevented liquid and gas, and meet the application requirements in many fields. For example, medical devices, machines and devices for everyday use, electronics, irrigation of devices, animal husbandry, etc.

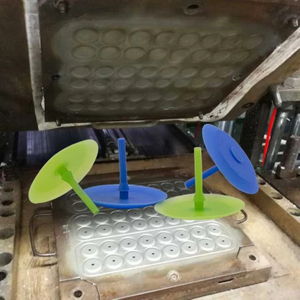

Duckbill Valve Design Key Point

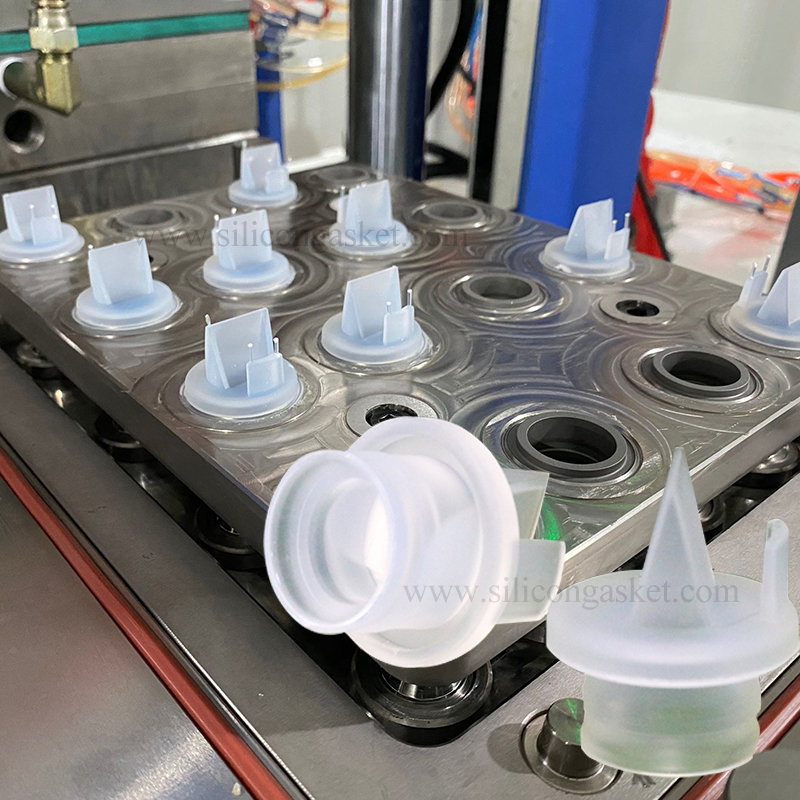

Duckbill Check Valves Quality, one depends on valves designs, materials & hardness choice, the other depends on slit cutting quality and equipment.

When Design the Duckbill Valve slit cutting, there should be a flat surface on the slit cutting side as the followed picture shows, or the die-cutting tool can not positionning.

Duckbill Valve Main Material

Duckbill Valves can be made from a variety of materials. The material choice is based on the nature of the material handled, temperature, pressure, and frequency of operation. Elastomeric duckbill valve materials are highly resistant to chemicals at high temperatures. However, the mechanical properties of elastomeric materials will be weakened at a higher temperature (above 150°F). High pressure can also destroy the valve. Another factor that can affect the duckbill valve function is the concentration of the media it will handle. The material may exhibit satisfactory corrosion resistance to certain corrodents up to a specific concentration and/or temperature. Examples of Duckbill Valve material and their specifications can be seen as below.

FDA food grade & medical grade Duckbill Valve are OK for repeated use for compliance with Food and Drug Administration Regulations, and can work at -40℃ to 230℃, at elevated temperatures, the tensile, elongation, and abrasion resistance is far superior to that of most organic elastomers. Low temperature flexibility is another advantage silicone has over most organic rubbers.

LSR & Liquid Silicone Rubber Duckbill Valves: Unlike conventional rubber, LSR can withstand extreme temperatures without changing its properties, enabling high heat autoclave sterilization or use in very cold environments

Fluorosilicone & FVMQ Duckbill Valves have good resistance of oil and strong acid | alkali |oxidant, and also have common silicone advantage like working temperature: -40oC ~ 230oC

EPDM Duckbill Valves have excellent performance at Ozone aging resistance, weather aging resistance & heat resistance.

Buna N & Nitrile Rubber Duckbill Valves performs excellently at oil resistance.

Duckbill Valve Main Application

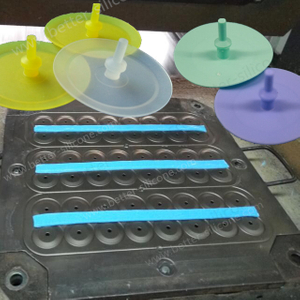

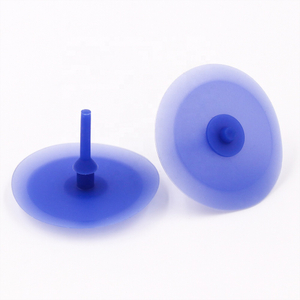

Ducbill Valves & LSR Duckbill Valve, as a sealing gasket and air & liquid flow control check valves and nipple nozzles, which is widely used in Breast Pump for mother and baby care products, is mainly made from FDA grade high-elastic silicone or LSR materials by compression molding & LIM.

Duckbill Valve & Medical Silicone Lip Valve, generally, made from low compression and high-tear resistance silicone & LSR, as duck shaped lips should open at low air pressure for pressure relief, and also critically close under higher air & hydraulic pressure for sealing & backflow functions. Duckbill Valve, generally, as a lip check valve and membrane seals & gaskets, which combinated with silicone tubing and plastic tube connectors as a one way valve or flow control valve components, like: Patient valve in manual resuscitator & respirator, CPR mask, Anesthesia apparatus & surgical eqipments, Sleep monitor, etc.

Our Duckbill Valves & Check Valves Production Advantage

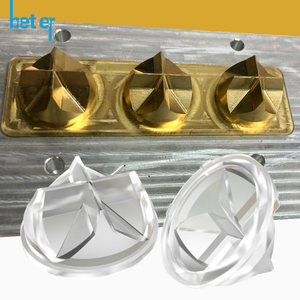

1. Precision mold-making technology

2. Rich experience of check valve molded production and slit cutting (critical sealing function, high & lower opening pressure)

3. In-depth knowledge of elastomer valves for different application and usage

4. Clean room for rubber valves production and assembly.

5. Professional engineers, QC and sales team: one-way valve's flow control technology

6. One-stop service: Silicone Rubber, Plastic & LSR molded production, assembly and packaging.

7. Value-added serice for one-way valve designs support according to your ideas and requirement details.