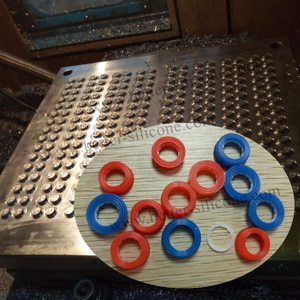

Silicone Rubber Kitchen Tap Nozzles

Silicone Showerhead Faucet Nozzles:

Basic Information:

Materials: Silicone

Features: Good Sealing, Water and Chloramine Resistance, High and Low Temperature Resistance, Ageing Resistance

Application: Bathroom Shower Head

Production Method: Rubber Compression Mold and LSR Injection Mold.

Production Standard: According to ASTM, DIN, JIS standard

Certification: WRAS, NSF, FDA, SGS etc.

Hardness ( Durometer): 30-95 Shore A (+/- 5 Shore A)

Temperature: -40 oC--- 230 oC

Color: Available.