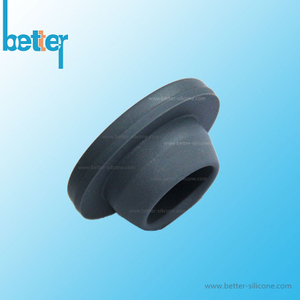

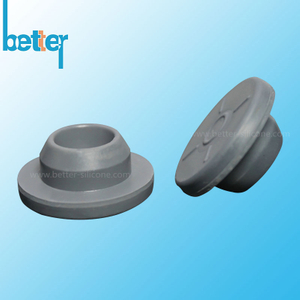

Chlorobutyl Rubber Stopper

Chlorobutyl Rubber Stopper, also called CIIR Stopper & Plug & Bung, as a medicine glass bottle sealing plug or cover, which made by compression tooling. Chlorobutyl Rubber is made from butyl rubber solution into chlorine gas,which chlorination occurs in the isoprene moiety and most of the substitution reaction is chlorine. The double bond of the butyl rubber is substantially completely preserved and corresponds to each of the isoprene double bond segments, which is substantially replaceable with one chlorine atom.

Chlorobutyl rubber can be regarded as copolymer of isobutylene and a small amount of chloro isoprene.The specific gravity of the product is 0.93, the product form white to light amber rubber block. Because chlorobutyl rubber is mostly saturated butyl skeleton, it has many specifics of butyl molecules:

Breathable and low moisture permeability, Shock absorption

Low glass transition temperature

Good aging and weather resistance in the atmospheric environment

Vulcanization diversity

Fast vulcanization

Good performance of metal followed Butyl rubber is also called IIR, “short for Isobutylene Isoprene Rubber”. Butyl rubber has good performance of chemical stability and thermal stability, the most prominent among which is the air tightness and watertightness. Its air permeability is only a 1/7 of natural rubber, and 1/5 of styrene butadiene rubber, while the vapor permeability is 1/200 of natural rubber, and 1/140 of styrene butadiene rubber 1/140. So it is mainly used for manufacturing various inner tubes, steam pipes, water tires, dam bottom and gaskets and other rubber products. In order to improve the poor blending of butyl rubber, halogenated butyl rubber appeared in 1960.

Advantages: halogenated butyl rubber not only has better performance of air tightness, hat also owns properties of heat resistance, ozone resistance, aging resistance, chemical resistance, and shock absorption, electrical insulation. halogenated butyl rubber can also be exposed to animal or vegetable oils or any other oxidizable chemicals.

Features of chlorobutyl rubber Stopper

Features of chlorobutyl rubber Stopper

Heat resistance

Chlorobutyl rubber has excellent heat resistance, and it has relatively low degradationin under the high temperature for a long time.Heat resistant properties of chlorobutyl rubber in addition to the factors with polymer itself, also related to the vulcanization system and reinforcing system.

Flexing resistance

As a important rubber species in manufacturing and anti-vibration article, flexing resistance performance of chlorobutyl rubber is very important. For its tight vulcanizates structure, chlorobutyl rubber has good flexing resistance. But on the other hand,chlorobutyl rubber hysteresis loss damage seriously, and heat production is also larger , so will reduce its flex resistance in the dynamic use.

Weather resistance

Weather resistance performance of chlorobutyl rubber has a good relationship with filler.Carbon black is an excellent UV resistant agent.With carbon black reinforcing of chlorobutyl rubber vulcanizate has a good weather resistance.Light color of vulcanizates has poorer weather resistance.

Air permeability

Chlorobutyl rubber has a very low air permeability, which is roughly the same as butyl rubber. At 24℃, chlorobutyl rubber gas permeability is only 1/9 of styrene butadiene rubber,1/4 of natural rubber.

Oil resistance

Chlorobutyl rubber are not of the oil resistant rubber, but it can make the vulcanizates oil resistance through appropriate coordination and has practical value.The better the vulcanization of vulcanized rubber, the better the oil resistance.In addition, using part of the oil-resistant rubber in the chlorobutyl rubber, can also improve the oil resistance of vulcanizate , such as nitrile rubber and chloroprene rubber.

Applications

Chlorobutyl rubber has all the inherent characteristics of butyl rubber, but also has a fast curing speed, co-vulcanizating with other rubber, more heat resistance, low compression deformation and so on. Therefore,its use is very wide. The main application areas include: tires, hoses, tape, industrial rubber products, pharmaceutical rubber products, sports product with rubbers, building sealing materials and chemical anti-corrosion lining.  Common Medicine Rubber Butyl Stopper: Bromobutyl Rubber Stopper and Chlorobutyl Rubber Stoppers.

Common Medicine Rubber Butyl Stopper: Bromobutyl Rubber Stopper and Chlorobutyl Rubber Stoppers. Chlorobutyl rubber and Bromobutyl rubber belong to butyl rubber derivatives by reacting butyl rubber, also known as halogenated butyl rubbers, which helps butyl rubbers to improve processing performance and expand a wider range of application. 1. Stabilizer Content:

Bromobutyl rubber contains active Bromine element, which result in lower storage stability and easy self-vulcanization. Therefore, Bromobutyl rubber usually need to be added stabilizer. However, chlorine element’s inertness in butyl rubber is stronger than Bromine element’s, so chlorobutyl rubber has a higher storage stability and then there’s usually no need to add stabilizer to butyl rubber, which makes inner contents higher purify.

2. Antioxidant Content:

Both of Chlorobutyl rubber and Bromobutyl rubber share the same proportion.

3. Property:

As industrial products, there is no essential difference in properties.

4. Machinability:

Bromobutyl rubber has high cure reactivity and it has a wide range of available curing systems. Common curing systems all are available for Bromobutyl rubber and the cure rate is faster.

Industrial products have a high requirement for physical properties, which usually adopt Brominated phenolic resin, stearic acid, zinc oxide, thiazole and thiuram accelerator as curing systems. In early period, Pharmaceutical Stoppers also adopted the these systems, but with a period of application, researchers found that these systems have certain influence on compatibility between medical Stoppers and Pharmaceutical. At present, domestic Bromobutyl rubber usually choose sulphur for curing for high efficiency and low cost.

However, Bromobutyl rubber has relatively low reactivity, which cause limitation of choosing curing systems. Besides, it still has strict requirement for manufacturing technique (relatively difficult). In the early days, phenolic resin, stearic acid and zinc oxide are usually used as curing system, contributing to good heat resistance. However, product’s extraction liquid is color-developing, which will affect Pharmaceutical clarity. Now, these curing systems are not used any more.

Advantages of chlorobutyl rubber Chlorobutyl rubber have better heat resistance, don’t tend to produce adhesion during high temperature sterilization and have higher efficiency during production.