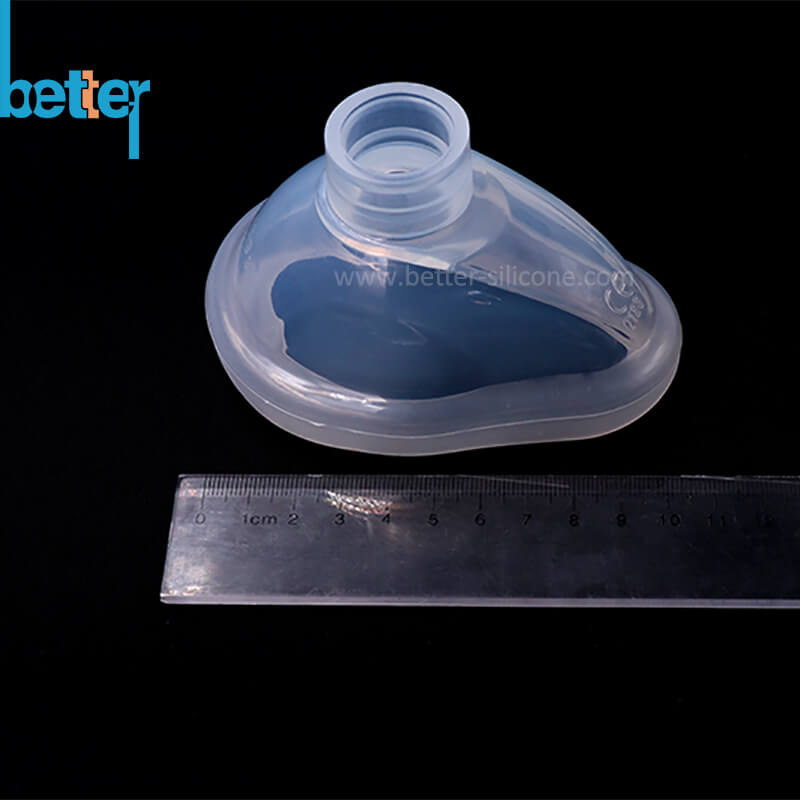

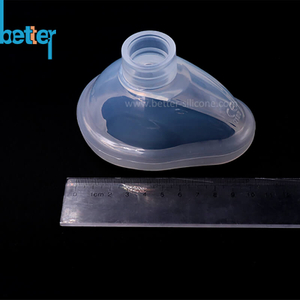

Silicone Resuscitator Mask Tooling

1. Tooling materials:

Compression Tooling: S136 Hot Treatment, imported NAK80 etc.

LSR Injection Mold : NAK80 etc.

PVC injection mold: 718H, S136, NAK80 etc.

2. Mask Materials:

Silicone: Wacker

LSR: Wacker, Dowcoming

PVC

3.Sizes/Types:

Neonate, Infant, Pediatric, Adult etc.(0#, 1#, 2#, 3#, 4#, 5#)

4. Disposable or Reusable:

Disposable Mask: PVC;

Reusable Mask: Silicone/LSR.

5.Working Temperature:

LSR Mask: -20°C - 450°C

Silicone Mask: -40°C- 230°C

PVC Mask: -10°C- 85°C

Our Advantage:

1. Own Mold-Making Technology (Since 1998)

2. Competitive Price: Origin Manufacturer.

3. Five experienced designers: offer technology/production/design/artwork support etc.

4. Production and Test strictly according to ISO9001.

5. Complete Production Plant, Equipment, Environment.

1. Five Plants:

Mold-Making Plant

Silicone Rubber Compressive Plant

Plastic Injection Plant

LSR Injection Plant (100,000 grade clean room)

Assembly Plants (100,000 grade clean room)

2. Mold-Making Equipment:

CNC, Mirror EDM, EDM, Slowspeed Wire Cut M/C and other auxiliary equipment etc.

3. Production Equipment:

15 Sets Rubber Compressive Machines, 8 Sets Haitian Plastic Injection Machines, 2 Sets LSR Injection Machines.

4. Test Equipment: 3D Projectors, Sealing Testor, Elasticity Measurement, Durometer etc.

5. Dustfree Environment: LSR injection Machines Assembly Line in 100,000 rating Dust-free Plants.

6. Fast-reaction:

The differences between liquid silicone rubber and solid silicone rubber

Silicone rubber can be divided into two types according to the form of existence, liquid silicone rubber and solid silicone rubber. Because of different forms of existence, they have distinct physical performances, which also results in significant differences in application. This article will discuss the differences between the liquid silicone rubber and solid silicone rubber.

Vulcanized silicone rubber products and mixed silicone rubber are solid. The solid silicone rubber we mention here is mixed silicone rubber, which is also known as high-temperature silicone rubber. This kind of silicone rubber can only be completely vulcanized in high temperature no matter which kinds of vulcanizing agent is used in order to get the ideal physical performance. Solid silicone rubber can be made into all kinds of silicone products after vulcanization, which generally have good physical properties. Solid silicone rubber can reach food grade standard by FDA approval after two-times vulcanization process. Thus, solid silicone rubber can be applied in both industry and foodstuff.

LSR has more variety, and it is liquid because it is made of original organic silicone material. Owing to the sulfur of movement, LSR is easier to form, so it can be easily made into mould used to copy product, which is what solid silicone rubber unable to meet. Moreover, it can also be made into adhesive being adhered to a variety of materials. The majority of LSR can be vulcanize at room temperature.

LSR can be divided into condensed type and addition type according to the reaction types. The former generally can not reach the food grade standard while the latter can do. Therefore, addition type LSR is used in all walks of life because of its very good physical properties.

Quickly Quotation Demands:

1.2D/3D designs Drawings, Samples, or other basic information

2.Materials Demands:

3. Surface and Shore A Demands.

4. Sizes Tolerance Demands: +/-0.005mm - +/-0.3mm

Notes:

1. Our company will not sell any silicone/LSR mask mold tooling to customers. Just accept orders which make-mold tooling and produce mask together.

2. Our company will not sell any ready silicone/LSR mask to other persons without our customer's permission

Please understand. Thanks