Laser Mark Engraving Etched Silicone Rubber Keypad

Laser mark silicone keypads are customized using translucent silicone rubber which is available in a variety of colors.

Generally, custom made laser mark rubber keypad, the materials choose transparent silicone rubber, which better than normal translucent silicone materials.

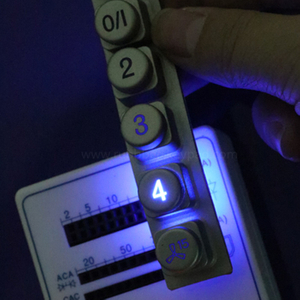

After finished basic compression transparent elastomer rubber keypads production, the laser mark keypads are sprayed opaque coating. First processing coated color (inner color) is same to the desired legends color, and the second processing coating color which is keypad surface colors.

After finished the laser keypads coating, puting the keypads into the laser mark machines for laser mark process.

Notes: Inner color and surface color gennerally is big color contrast.

Like inner plating color is white, the surface color mostly choose black.

Choose inner translucent silicone keypad with gray or black color keypad to do laser mark process, the keypad can't shows laser mark characters without backlight.

Xiamen Better Silicone Co.,Ltd can help you decide which are suitable for your particular laser mark rubber keypads. Main Silicone Rubber Keypads 1. Silk Screen Silicone Keypad 2. Laser Mark Silicone Keypad 3. Epoxy Coating Silicone Keypad 4. P+R Keypad 5. Double Color Silicone Keypad 6. Backlight Silicone Keypad 7. Fluorescent Silicone Keypad 8. Conductive Printing Silicone Keypad 9. M+R Keypad  Quickly Quotation Requirements 1. Offer 2D, 3D design (PDF, CAD, STEP, IGS, slprt. ) drawings, or samples 2. Include number of legend and silicone colors, Of need silicone light guide. 3. With or without carbon pills 4. Keypads surface demands: Laser Etched, Silkscreen, Spray Coating, UV Coating etc. 5. Quantities to be quoted These are the primary elements for a quotation. Other details such as travel, force, durometer and tactile response can be determined at the time of order.Specialty features such as protective coatings, laser mark, light pipes, etc. should be included.

Quickly Quotation Requirements 1. Offer 2D, 3D design (PDF, CAD, STEP, IGS, slprt. ) drawings, or samples 2. Include number of legend and silicone colors, Of need silicone light guide. 3. With or without carbon pills 4. Keypads surface demands: Laser Etched, Silkscreen, Spray Coating, UV Coating etc. 5. Quantities to be quoted These are the primary elements for a quotation. Other details such as travel, force, durometer and tactile response can be determined at the time of order.Specialty features such as protective coatings, laser mark, light pipes, etc. should be included. | Silicone Keypad Surface Process | UV Coating, Laser Mark, Silly Printing, Spray Coating etc. |

| Plastic Keycap Surface Process | UV Coating, Metallic Plated, Light Guide etc |

| Combination | Glue |

Our Advantage: 1. Precision Own Mold-Making Technology (Since 1998) 2. Competitive Price: Origin Manufacturer.

1.) Mold-Making Plant

2.) Silicone Rubber Compression Plant

3.) Plastic Injection Plant

4.) Liquid Silicone Rubber Injecton Plant (LSR)

5.) Assembly Plant.

3. Five Experienced Designers and Engineers

4.Production and Test strictly according to ISO9001. Test Equipment: 3D Projectors, Sealing Testor, Elasticity Measurement, Durometer etc. 5. Production Environment 6. Rapid Reaction Organization: Support Customer at short time