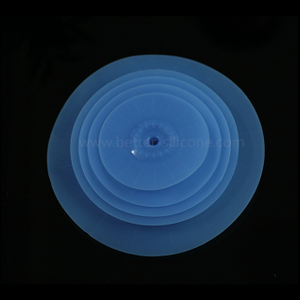

Rubber Silicone Ear Plugs

Silicone Ear Plugs, also known as Silicone Earplugs, Silicone Earbud covers& Tips , are designed to be fitted comfortably and firmly into user’s ears for voice output, which are common electronic accessories for various cell phone earbud. Silicone Earplug also can be used to protect the user’s ears from loud noises, instruction of water, dust and foreign objects in different fields (Sleeping, Swimming, industry, etc)

Silicone Ear Plugs are mainly produced by Silicone Rubber Compression Mold Tool and LSR (Liquid Silicone Rubber) Injection Mold Tool.

Elastomeric Ear Plugs are typically made out of soft silicone material with hardness 30-55 Shore A, which are soft, anti-dust, anti-slip and have shock-proof features so as to extend life span of earphone.

Silicone Ear Plugs are fitted in the outer ear or are inserted directly in the ear canal (In-ear headphones for voice output and used for ears protection, so the silicone material need to meet all food grade and medical requirements or certification, like USP Class VI, FDA 21 CFR 177.2600, etc.

Silicone Ear Plugs' dimension, hardness, structure and surface processing have an important effect on fitting stability and sealing condition. Besides, the surface processing also influence the beauty of silicone earplugs. Therefore, there is very some strict requirements for the production of Silicone Ear Plugs.

1. Minimize the parting line (joint line) to make beautiful surface

2. Do matte smooth coating on Ear Plug’s surface, which can comfortable contact and anti-dust effect.

3. Adopt FDA and Medical grade material during the whole manufacturing procedure, including silicone material, pigment (for customized color) and release agent.

4. Process mold tool by precision Mirror surface EDM machine, which make silicone ear plugs higher precision so as to produce exactly suitable dimension for individual’s ears.

(Notes: Mirror surface EDM machine processing is usually used for high precision silicone rubber compression mold tool, LSR(liquid silicone rubber) or Plastic Injection Mold, especially the precise processing on some complicated aspherical surface of mold base, which makes components higher quality, more precise dimension and more exact dimensions for your application.

Xiamen Better Silicone Import and Export Co., Ltd, which making Rubber Compression / plastic injection /Liquid Silicone Rubber Injection mold tool and producing silicone rubber compression parts, plastic injection parts, Liquid silicone rubber injection parts.

We have in-depth knowledge of silicone ear plugs mold-making technology and Earplugs molded technology. Therefore we will control the minimized parting line and most exact dimensions for your products.

Our Advantages:

1. Own Precision Silicone Rubber Compression Mold-making Technology

2. Precision Silicone Rubber Compression, like for Smart Cellphone Parts, Medical Parts. (precision silicone rubber compression parts size tolerance can up to +/-0.01mm)

3. Liquid silicone rubber injection mold and production.