Adhesive Backing Gum Glue Silicone Rubber Sheet

Adhesive Backing Gum Glue Silicone Rubber Sheet is also called Adhesive Glue Rubber Pads, Backing Side Gum Rubber Seal, and Adhesive Silicone Rubber Gasket, which is made of elastomeric silicone rubber materials with Single Backing / Rear or Double Sides Glue Gum Adhesive Tape.

Bonding to which materials and Bonding Environment choose different Adhesive Backing Glue Gum materials.

Bonding Materials like plastic, metal, glass, wood, rubber etc.

Bonding Environment: Outside, High Temperature, Cold Temperature, Water, Dust etc.

Silicone Rubber Sheet with Adhesive Backing Glue Gum Tape is in aim to improve the water-proof and dust proof function of electronic products. Generally using IPxx code to identify the waterproof grade and anti-dust grade. Such as IP 55, IP56, IP57, IP 65, IP66, IP67 etc.

Backing Adhesive Rubber Sheet Basic Information

1. Function: Products Sealing.

2. Rubber Sheet Common Materials

NR, NBR, EPDM, HNBR, Silicone, SBR, TPU, PTV, CR, XNBR, LSR (Liquid Silicone Rubber, LSR elastosil) etc.

3. Adhesive Bonding Materials: Plastic, Rubber, Steel, Glass, Wood etc.

3. Silicone Rubber Adhesive Sheet Special Demands

1) IP grade (dust/water proof grade, 3M gumming tape),

2) Conductive Silicone Rubber Adhesive Sheet

3) Anti-Fire grade (flame retardant) (UL94 VO),

4) Medical / food standards(FDA PTFE), (If really need up to completely food/medical standard, the best choose LSR) SGS reports etc.4) Silicone Glue Gasket Hardness: 30-85 shore A. (Hardness Tolerance: +/- 5 shore A)

5) Sizes Tolerance +/-0.01mm - +/-0.3mm

6) Silicone Adhesive Sheet Working Temperature: -40℃- 230℃

Adhesive Glue Silicone Rubber Sheet 3M Tape Classifications

| Acrylic Foam Tapes | Transfer Tapes | Double Coated Tapes |

| 3M™ VHB™ | 3M™ 467 | 3M™ 9415 |

| 3M™ DC2008 | 3M™ 927 | 3M™ 9425 |

| 3M™ DC2011 | Adchem 728 | Tesa® 4959 |

| 3M™ PT1100 | Re-Closable Fasteners | Tesa® 4965 |

| 3M™ EX4011 | 3M™ Dual Lock™ | Tesa® 62855/56 |

| Adchem 728 | VELCRO® hook and loop | Adchem 254 |

Adhesive Silicone Rubber Sheet Main Applications

The application of Adhesive Silicone Rubber Sheet is rapidly growing in the industrial manufacturing market. Such as Smart Phone products, Electronic Housing, Medical Device, etc.

Our Advantages for Making Backing Adhesive Gum Glue Silicone Rubber Sheet

1. Technology: Precision Own Mold-Making Technology

Our Silicone Rubber Compression Parts Sizes Tolerance can up to +/-0.02mm, Some can up to 0.01mm

2. Price Advanatge:

Own Rubber Compression Plant, Plastic Injection Plant, Liquid Silicone Rubber Injection Plant and Assembly Plant

3. Experienced Advantage:

Making Mold: 1998 year

Rubber Compression: 2002 year

Plastic Injection: 2005 year

Liquid Silicone Rubber Injection: 2012 year

Products Assembly: 2012 year

4. Quality Advantage:

Regarding Backed Adhesive Glue Silicone Rubber Gasket, we mainly working with local Backing Glue companies since 2009 years, and now have three good backing glue companies help us deal with it.

Our company would check the final backing adhesive silicone rubber gasket quality before delivery.

5. One-Stop Service:

Our company will work closely with you to determine the best pressure sensitive silicone rubber Backed Adhesive Sheet for your applications.

If customers tell us which bonding materials and bonded environments. we will offer our suggests about backing adhesive gums for choose.

Quick Quotation and OEM/ODM Requirements

| 1. | Drawings Demands: | Offfer 2D/3D drawings or other basic information |

| 2. | Materials Demands: | Silicone, NBR, EPDM, SBR etc or TPU, LSR |

| 3. | Bonded Materials: Plastic, Rubber, Metal, Glass, Wood etc. |

| 4. | Bonding Environment Demands: Outside, High Temperature, Water-proof, Dust-free ect. |

| 5. | Backing Adhesive Glue Gum Tape Demands | 3m, Sony ect. |

| 6. | Packaging Demands |

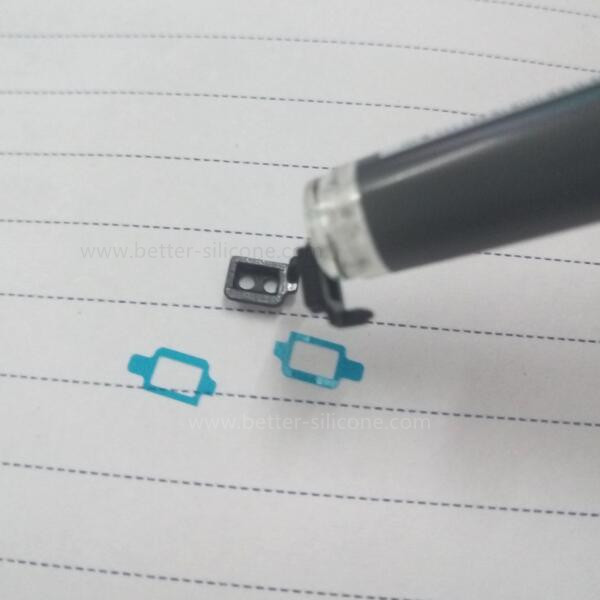

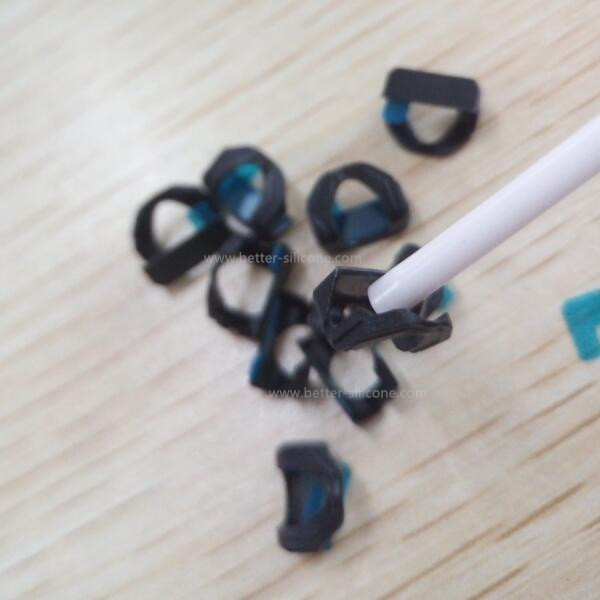

Backing Adhesive Silicone Rubber Sheet Technological Processes

1. Making Mold Tooling first

2. After finishing mold, producing silicone rubber samples (about 5-10 molds) for test.

Test each cavity silicone rubber sample by 3D projectors if dimensions are within tolerances. Some precision samples need to cut (cutting cross section) which is easy to test the sizes and designs.

3. If dimensions are ok, sending the whole piece of silicone products to factory for dealing with silicone glue.

Notes:

1. If big silicone rubber sheet, burring firstly, and then deal with silicone glue.

If small silicone rubber gasket, generally dealing with silicone glue firstly, and then choose fixture tooling (cutting/punching die) to burring. Or removing the big burrs, and then deal with the silicone glue gum, finally fixture tooling (cutting/punching die) to burring.

Backed Rubber Sheet Adhesive Glue Tape Process

1. Paste double sided silicone adhesive tape with the anti-adhesive sides of anti-adhesive paper;

2. Cutting the inner round holes by cutting die;

3. Silicone products are coated with silica gel treatment agent; (Notes: silica gel treatment agent should be even/ well-distributed; and should not coat on the surface of silicone products)

4. Rightly placed stick double sides silicone 3m tape, the surface of 3m tepe should be even. (Notes: should not be a little off; and should not have bubble.)

5. Next Die Cutting for burring

6. After finishing die cutting, check if have less materials or not clear cutting.

7. Test the finished products by 3D projects and amplification instrument